How does building red board withstand the pressure of high-strength concrete pouring without buckling?

Release Time : 2025-08-27

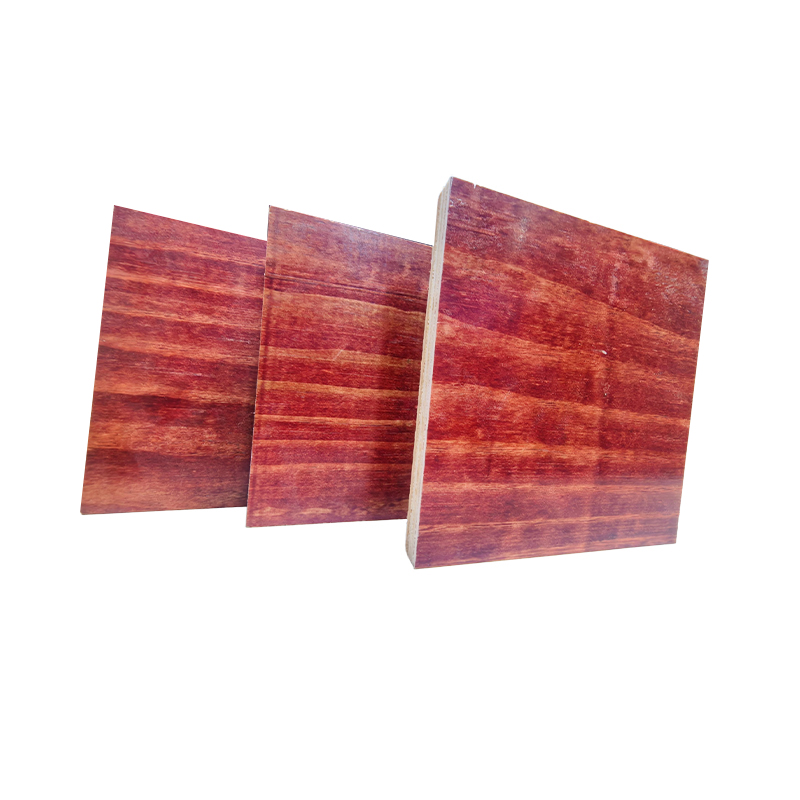

In modern construction, the quality and formability of concrete structures depend heavily on the performance of the formwork system. As one of the most commonly used formwork materials, building red board, named for its red melamine resin coating, is widely used in formwork for cast-in-place concrete structures such as shear walls, columns, beams, and floor slabs. Faced with wet concrete weighing up to 2.4 tons per cubic meter and generating significant lateral pressure during pumping,...

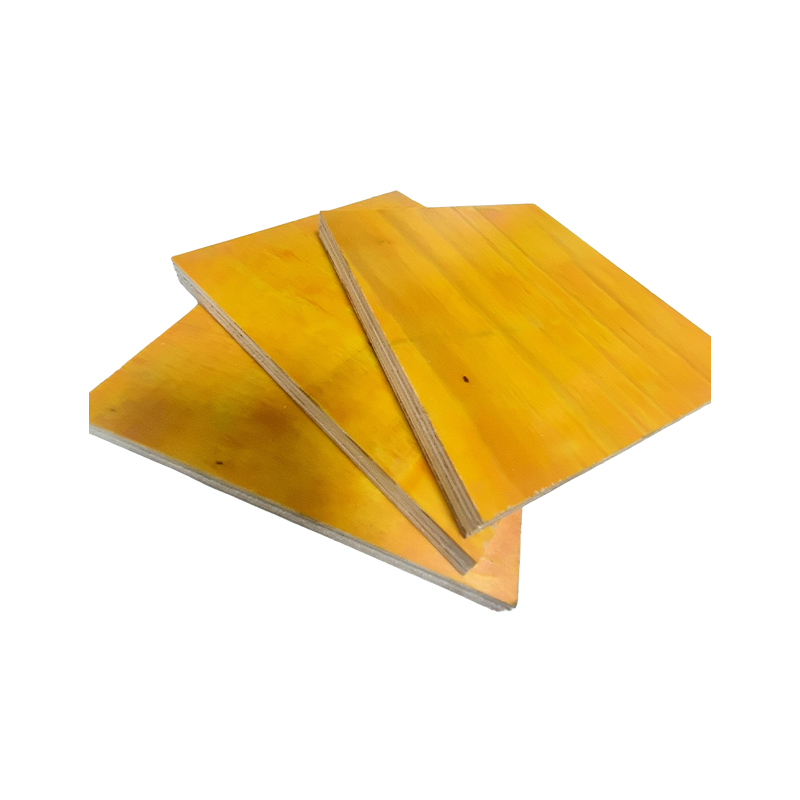

1. Core Material: Multi-layer Glued-Layer Structure Provides Strong Bending Rigidity

Building red board is essentially a high-strength wood plywood, constructed from multiple layers of peeled poplar, birch, or eucalyptus veneer, hot-pressed and glued together with the fibers of adjacent layers perpendicular to each other. This cross-laminated structure effectively distributes external loads and avoids the anisotropic weaknesses of a single wood material. The number of layers is typically 9 to 15, with a thickness ranging from 12 mm to 18 mm. Thicker boards offer increased bending strength and stiffness. The multi-layer structure prevents the red board from buckling or sagging when subjected to lateral pressure from concrete, providing the foundation for its "bend-proof" performance.

2. Red Film: More Than Just a Color, a Functional Enhancement Layer

The glossy red film on the surface isn't simply dyed; it's a reinforced film impregnated with melamine-formaldehyde resin. Cured under high temperature and pressure, this film exhibits the following key properties:

High Hardness and Abrasion Resistance: The surface has an increased Mohs hardness, resisting scratches from rebar binding and concrete pouring, maintaining a smooth surface.

High Water Resistance: Effectively blocks moisture penetration from the concrete, preventing the board from swelling, delamination, and delamination, maintaining structural stability.

Low Water Absorption and Excellent Release: The dense and smooth film resists adhesion to concrete, resulting in a smooth surface after demolding, reducing repairs and maintaining performance even after repeated use.

This film not only extends the lifespan of the red board but also maintains its surface integrity under high pressure, preventing localized deformation caused by surface damage.

3. Scientific Formwork: Systematic Collaboration Achieves Overall Stability

The strength of a single piece of building red board is limited, and its ability to withstand pressure without bending ultimately depends on a complete formwork support system. During construction, red board is typically combined with wooden backing strips, steel pipe main strips, tie rods, and adjustable steel supports. The wooden strips serve as secondary studs, fixed horizontally or vertically to the back of the red board, evenly transferring lateral concrete pressure to the primary studs. The tie rods pass through the wall formwork and are locked at both ends to prevent outward bulging. The steel supports provide vertical load-bearing and lateral stability. This systematic design transforms local loads into an overall force, preventing bending or bulging of the red board due to uneven load distribution.

4. High Endurance: Maintaining Performance Through Repeated Use

High-quality building red board can be used over 10 to 15 times with proper use and maintenance. The adhesive layer is made of waterproof phenolic resin (PF) adhesive, which is resistant to boiling and high temperatures, and resists debonding even in humid environments or steam curing conditions. Edges are typically sealed to further prevent moisture intrusion from the sides and extend its service life. With each turnover, as long as there is no significant damage or delamination, its structural strength will continue to meet construction requirements.

5. Balancing Economy and Construction Efficiency

Compared to steel or aluminum alloy formwork, building red board offers lower cost, lighter weight, and easier cutting and processing, making it adaptable to a variety of complex structures. While the cost per use is slightly higher, its overall cost-effectiveness is significantly superior in the construction of low- and medium-rise buildings and non-standard floors. Its "bending under pressure" performance strikes the optimal balance between cost, efficiency, and safety.

Building red board's ability to withstand pressure and remain stable during high-strength concrete pouring is not due to a single factor, but rather stems from the mechanical advantages of its multi-layered glued structure, the enhanced functionality of the red film, the synergistic effect of its scientific formwork system, and the durability of its high-quality adhesive. It is more than just a "form" for concrete; it serves as the "first line of defense" for construction safety and quality. On modern construction sites, this seemingly ordinary "red board" silently supports the skeleton of each high-rise building with its reliable performance.

1. Core Material: Multi-layer Glued-Layer Structure Provides Strong Bending Rigidity

Building red board is essentially a high-strength wood plywood, constructed from multiple layers of peeled poplar, birch, or eucalyptus veneer, hot-pressed and glued together with the fibers of adjacent layers perpendicular to each other. This cross-laminated structure effectively distributes external loads and avoids the anisotropic weaknesses of a single wood material. The number of layers is typically 9 to 15, with a thickness ranging from 12 mm to 18 mm. Thicker boards offer increased bending strength and stiffness. The multi-layer structure prevents the red board from buckling or sagging when subjected to lateral pressure from concrete, providing the foundation for its "bend-proof" performance.

2. Red Film: More Than Just a Color, a Functional Enhancement Layer

The glossy red film on the surface isn't simply dyed; it's a reinforced film impregnated with melamine-formaldehyde resin. Cured under high temperature and pressure, this film exhibits the following key properties:

High Hardness and Abrasion Resistance: The surface has an increased Mohs hardness, resisting scratches from rebar binding and concrete pouring, maintaining a smooth surface.

High Water Resistance: Effectively blocks moisture penetration from the concrete, preventing the board from swelling, delamination, and delamination, maintaining structural stability.

Low Water Absorption and Excellent Release: The dense and smooth film resists adhesion to concrete, resulting in a smooth surface after demolding, reducing repairs and maintaining performance even after repeated use.

This film not only extends the lifespan of the red board but also maintains its surface integrity under high pressure, preventing localized deformation caused by surface damage.

3. Scientific Formwork: Systematic Collaboration Achieves Overall Stability

The strength of a single piece of building red board is limited, and its ability to withstand pressure without bending ultimately depends on a complete formwork support system. During construction, red board is typically combined with wooden backing strips, steel pipe main strips, tie rods, and adjustable steel supports. The wooden strips serve as secondary studs, fixed horizontally or vertically to the back of the red board, evenly transferring lateral concrete pressure to the primary studs. The tie rods pass through the wall formwork and are locked at both ends to prevent outward bulging. The steel supports provide vertical load-bearing and lateral stability. This systematic design transforms local loads into an overall force, preventing bending or bulging of the red board due to uneven load distribution.

4. High Endurance: Maintaining Performance Through Repeated Use

High-quality building red board can be used over 10 to 15 times with proper use and maintenance. The adhesive layer is made of waterproof phenolic resin (PF) adhesive, which is resistant to boiling and high temperatures, and resists debonding even in humid environments or steam curing conditions. Edges are typically sealed to further prevent moisture intrusion from the sides and extend its service life. With each turnover, as long as there is no significant damage or delamination, its structural strength will continue to meet construction requirements.

5. Balancing Economy and Construction Efficiency

Compared to steel or aluminum alloy formwork, building red board offers lower cost, lighter weight, and easier cutting and processing, making it adaptable to a variety of complex structures. While the cost per use is slightly higher, its overall cost-effectiveness is significantly superior in the construction of low- and medium-rise buildings and non-standard floors. Its "bending under pressure" performance strikes the optimal balance between cost, efficiency, and safety.

Building red board's ability to withstand pressure and remain stable during high-strength concrete pouring is not due to a single factor, but rather stems from the mechanical advantages of its multi-layered glued structure, the enhanced functionality of the red film, the synergistic effect of its scientific formwork system, and the durability of its high-quality adhesive. It is more than just a "form" for concrete; it serves as the "first line of defense" for construction safety and quality. On modern construction sites, this seemingly ordinary "red board" silently supports the skeleton of each high-rise building with its reliable performance.