How does building formwork gold board work together to ensure concrete forming accuracy?

Release Time : 2025-09-11

In modern construction, the quality of concrete structure forming is directly related to the building's safety, durability, and aesthetic quality. To achieve high-precision and efficient construction, building formwork systems must possess exceptional strength, stability, and dimensional consistency. Building formwork gold board, widely used in recent years in projects such as buildings, bridges, and tunnels, has become a core component for ensuring precise concrete forming thanks to its high strength, lightweight, smooth surface, and systematic design. This formwork system comprises four subsystems: the formwork body, support system, fasteners, and supporting accessories. Through scientific integration and precise coordination, it creates a stable, reliable, and non-deformable overall structure during the concrete pouring process, ensuring that the final component achieves the required geometric accuracy and surface quality.

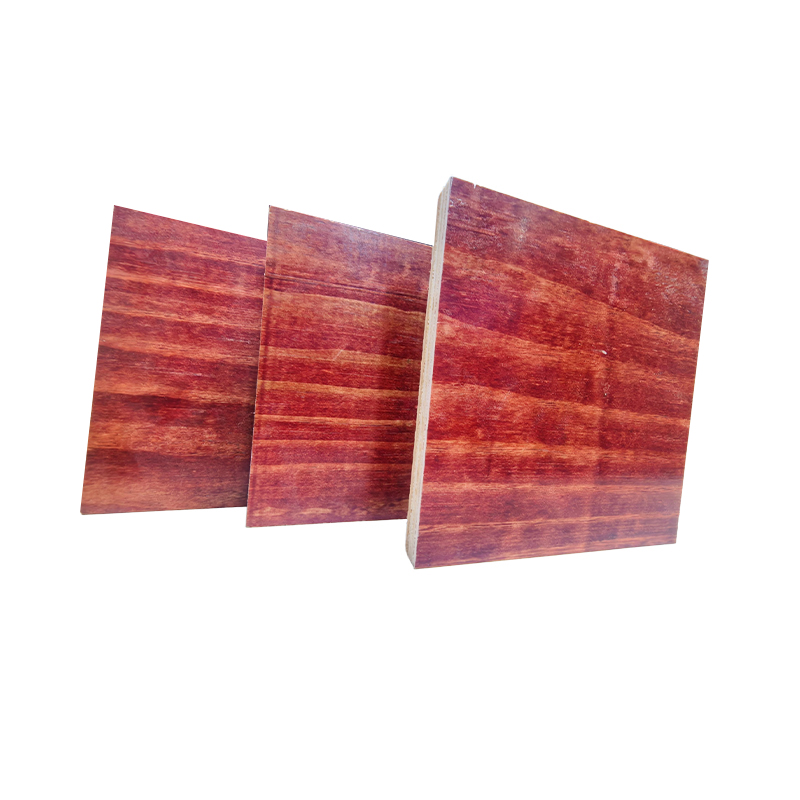

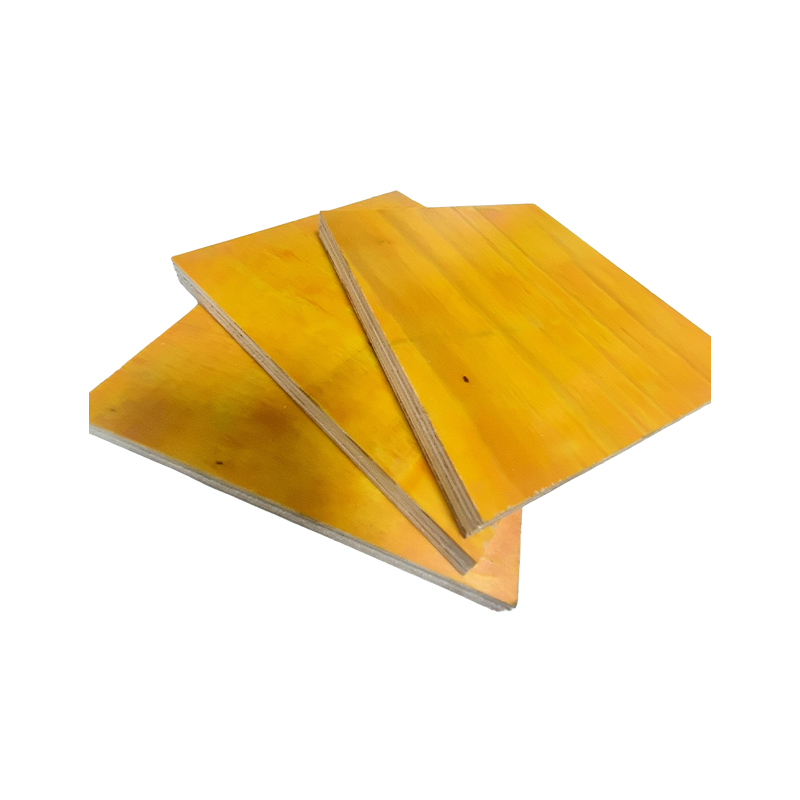

1. High-Precision Formwork Body: Providing a Smooth and Stable Forming Surface

Building formwork gold board utilizes high-quality woods such as poplar and pine as its core material. After drying, it eliminates internal stresses and prevents warping or cracking during use. The surface is covered with high-strength impregnated paper and formed in a single press process at high temperature and high pressure, resulting in extremely high density and hardness. A double-layer surface curing treatment further strengthens the surface layer, forming a dense protective film. This not only enhances wear and pressure resistance but also effectively prevents cement slurry penetration and adhesion, ensuring smooth demolding and a smooth surface. The formwork edges utilize integrated vertical and side frame reinforcements, reducing traditional weld joints and preventing localized deformation caused by weld cracking, significantly improving overall rigidity. Customizable thickness and dimensions allow for precise matching with the design requirements of different walls, columns, or beams, ensuring assembly accuracy from the very beginning.

2. Scientific Support System: Resists Lateral Pressure During Concrete Pouring and Prevents Formwork Deformation

Concrete pouring generates significant lateral pressure, particularly in high-rise walls or large structures, which can easily cause formwork bulging, displacement, or even collapse. The Building Formwork Gold Board system features a dedicated steel or aluminum alloy support frame, utilizing a combination of adjustable vertical posts, horizontal braces, and diagonal braces to create a stable, load-bearing structure. Support spacing is strategically arranged based on the calculated load, ensuring even load distribution across each formwork. The support base features an adjustable base to accommodate uneven surfaces, while the top features limiter slots for a secure connection to the formwork, preventing it from lifting. This system can not only withstand tons of lateral pressure but also allows for rapid assembly and disassembly, improving construction efficiency.

3. Standardized Fasteners and Connectors: Achieve Seamless Connections and Precise Positioning

The quality of the connections between formwork directly impacts the smoothness of concrete joints. The Jinban system utilizes specialized quick-release fasteners, combined with frame reinforcements, to ensure a tight fit between formwork, minimizing gaps to within 1mm and eliminating grout leakage. Accessories such as corner forms, adapters, and end caps are designed using standard modules, supporting various joints such as right-angle, T-shaped, and L-shaped connections, ensuring precise forming even for complex structures. No on-site welding or drilling is required at all connection points, minimizing damage and extending formwork turnover.

4. System Synergy: Creating a Stable and Reliable Forming Environment

The four major systems do not exist in isolation; instead, they are highly integrated through unified modular design and installation specifications. The formwork provides the forming surface, supports and bears the load, fasteners secure the structure, and accessories complete the details, collectively creating a rigid, minimally deformed, and well-sealed enclosed space. During construction, workers can quickly assemble the formwork according to pre-set plans, significantly reducing the formwork cycle. During pouring, the system exhibits excellent vibration resistance, preventing vibration or shifting even from the impact of pumped concrete, ensuring that wall thickness, verticality, and flatness meet regulatory requirements.

Building Formwork Gold Board utilizes high-performance materials, advanced processes, and systematic design to achieve high-precision control during the concrete forming process. The coordinated operation of its four systems not only improves construction quality and safety, but also promotes the development of building industrialization and green construction.

1. High-Precision Formwork Body: Providing a Smooth and Stable Forming Surface

Building formwork gold board utilizes high-quality woods such as poplar and pine as its core material. After drying, it eliminates internal stresses and prevents warping or cracking during use. The surface is covered with high-strength impregnated paper and formed in a single press process at high temperature and high pressure, resulting in extremely high density and hardness. A double-layer surface curing treatment further strengthens the surface layer, forming a dense protective film. This not only enhances wear and pressure resistance but also effectively prevents cement slurry penetration and adhesion, ensuring smooth demolding and a smooth surface. The formwork edges utilize integrated vertical and side frame reinforcements, reducing traditional weld joints and preventing localized deformation caused by weld cracking, significantly improving overall rigidity. Customizable thickness and dimensions allow for precise matching with the design requirements of different walls, columns, or beams, ensuring assembly accuracy from the very beginning.

2. Scientific Support System: Resists Lateral Pressure During Concrete Pouring and Prevents Formwork Deformation

Concrete pouring generates significant lateral pressure, particularly in high-rise walls or large structures, which can easily cause formwork bulging, displacement, or even collapse. The Building Formwork Gold Board system features a dedicated steel or aluminum alloy support frame, utilizing a combination of adjustable vertical posts, horizontal braces, and diagonal braces to create a stable, load-bearing structure. Support spacing is strategically arranged based on the calculated load, ensuring even load distribution across each formwork. The support base features an adjustable base to accommodate uneven surfaces, while the top features limiter slots for a secure connection to the formwork, preventing it from lifting. This system can not only withstand tons of lateral pressure but also allows for rapid assembly and disassembly, improving construction efficiency.

3. Standardized Fasteners and Connectors: Achieve Seamless Connections and Precise Positioning

The quality of the connections between formwork directly impacts the smoothness of concrete joints. The Jinban system utilizes specialized quick-release fasteners, combined with frame reinforcements, to ensure a tight fit between formwork, minimizing gaps to within 1mm and eliminating grout leakage. Accessories such as corner forms, adapters, and end caps are designed using standard modules, supporting various joints such as right-angle, T-shaped, and L-shaped connections, ensuring precise forming even for complex structures. No on-site welding or drilling is required at all connection points, minimizing damage and extending formwork turnover.

4. System Synergy: Creating a Stable and Reliable Forming Environment

The four major systems do not exist in isolation; instead, they are highly integrated through unified modular design and installation specifications. The formwork provides the forming surface, supports and bears the load, fasteners secure the structure, and accessories complete the details, collectively creating a rigid, minimally deformed, and well-sealed enclosed space. During construction, workers can quickly assemble the formwork according to pre-set plans, significantly reducing the formwork cycle. During pouring, the system exhibits excellent vibration resistance, preventing vibration or shifting even from the impact of pumped concrete, ensuring that wall thickness, verticality, and flatness meet regulatory requirements.

Building Formwork Gold Board utilizes high-performance materials, advanced processes, and systematic design to achieve high-precision control during the concrete forming process. The coordinated operation of its four systems not only improves construction quality and safety, but also promotes the development of building industrialization and green construction.