Unveiling the Secrets of Why Building Film Faced Panels Have Become a Favorite in Modern Architecture

Release Time : 2025-09-23

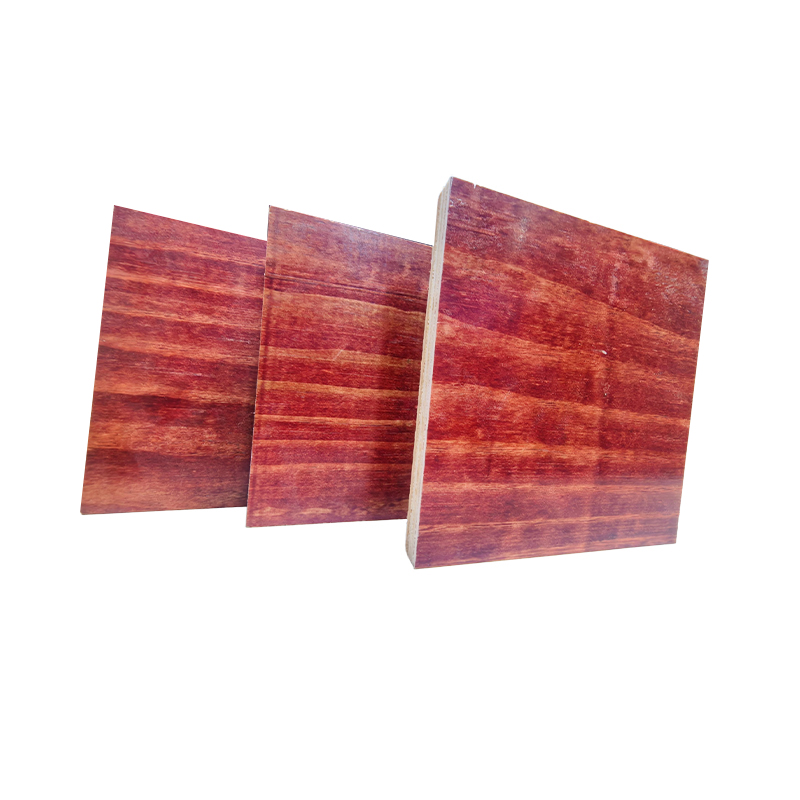

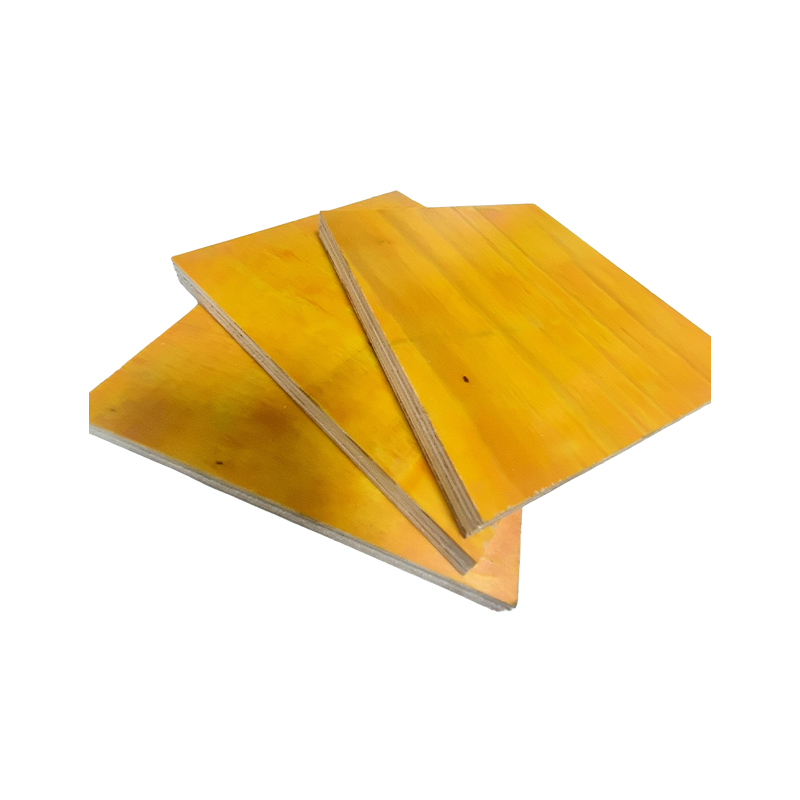

I. Building Film Faced Panels

In modern construction, with increasing demands for building quality, construction efficiency, and environmental protection, the research and application of new building materials has become increasingly critical. As an innovative building material, building film faced panels, with their unique performance advantages, have rapidly become an indispensable component in the concrete forming process. They are widely used in various projects, including high-rise buildings, bridges, and tunnels, providing strong support for the development of modern architecture. This article will comprehensively and in-depth analyze the characteristics, applications, and significant advantages of building film faced panels, aiming to provide a comprehensive and practical reference for those involved in the construction industry.

II. Characteristics of Building Film Faced Panels

2.1 Material Composition and Careful Screening

The performance of building film faced panels is fundamentally based on their high-quality base material. Due to differences in climate and wood resources between northern and southern my country, material selection is tailored to local conditions. Northern China often uses high-quality birch and poplar, while southern China prefers pine and eucalyptus. These woods undergo a rigorous and meticulous screening process before being used. The screening criteria are extremely stringent, requiring the wood to be scar-free, crack-free, uniform in density, and possess high bending strength. This rigorous screening ensures that each substrate is of exceptional quality, laying a solid foundation for subsequent coating adhesion and overall board performance stability, effectively enhancing the durability and overall performance of the film-faced panels.

2.2 Excellent Surface Finish and Precision

The film-faced panels utilize a meticulously polished surface treatment process, achieving a mirror-like finish with a flatness tolerance of ≤0.02 mm/m. This high-precision surface treatment is crucial in many ways. During the demolding process, the smooth surface provides an ideal interface for concrete separation, significantly simplifying demolding and ensuring a smooth and complete separation of the concrete surface from the formwork. Furthermore, this high-quality demolding ensures an exceptionally smooth concrete surface, reducing the workload and cost of subsequent surface treatment. Furthermore, the smooth surface improves construction efficiency, reduces delays caused by formwork surface defects, and accelerates project progress.

2.3 Excellent Mechanical Properties

Mechanical properties are one of the core advantages of architectural film facing panels. Its static flexural strength is exceptional, more than twice that of ordinary wood, providing a strong load-bearing capacity. In actual engineering applications, it can easily withstand lateral concrete pressures of up to 60 kN/m². This characteristic makes architectural film facing panels irreplaceable in the construction of key structural components of high-rise buildings, such as shear walls, beams, and columns. In these structures subjected to heavy loads, architectural film facing panels maintain stability and provide reliable support, ensuring the safety and stability of the building and effectively resisting various external forces.

2.4 Reliable Fire and Chemical Resistance

Architectural film facing panels offer excellent safety and protection. Their covering layer achieves a B1 fire rating, a significant fire resistance performance in the field of building safety. In the event of a fire, they effectively slow the spread of fire, buying valuable time for evacuation and rescue efforts, and significantly reducing damage to the building and its residents. This fire resistance is particularly critical in high-rise buildings and those with complex structures. Furthermore, the phenolic resin adhesive layer in building film panels plays a crucial role in chemical protection. It acts as a solid barrier, effectively isolating moisture and chemicals, preventing these harmful substances from corroding and contaminating the concrete. This extends the service life of the formwork, reduces the need for frequent replacement and maintenance due to formwork damage, and lowers project costs.

III. Applications of Building Film Panels

3.1 High-Rise Building Construction

Building film panels play a vital role in high-rise building projects. Their high strength and excellent surface finish make them an ideal choice for forming key structural components such as shear walls, beams, and columns. During the concrete pouring process, building film panels can withstand the immense pressure of concrete, ensuring that the formwork remains stable during the pouring and curing phases, preventing deformation or damage due to excessive pressure. This stability ensures the dimensional accuracy and surface quality of the concrete components, resulting in high-quality concrete components that meet stringent standards and provide a solid foundation for the overall quality of high-rise buildings. Furthermore, their efficient construction performance helps shorten the construction period of high-rise buildings and improve project efficiency.

3.2 Bridge and Tunnel Construction

Bridge and tunnel construction places extremely stringent demands on formwork materials, requiring high strength, durability, and excellent environmental adaptability. Architectural film panels, with their superior mechanical properties and exceptional resistance to environmental factors, perfectly meet these requirements. During bridge construction, bridge structures are exposed to the elements for extended periods, facing multiple challenges such as moisture, chemical corrosion, and fire hazards. The fire and chemical resistance of architectural film panels effectively address these challenges, protecting the safety and durability of bridge structures. Tunnel construction, characterized by relatively confined construction space, places high demands on concrete surface quality. The smooth surface finish of architectural film panels facilitates demoulding, significantly reducing the risk of concrete surface defects such as honeycombing and roughness, thereby improving the quality and aesthetics of tunnel construction.

3.3 Other Construction Projects

In addition to large-scale projects such as high-rise buildings, bridges, and tunnels, architectural film panels are widely used in various construction projects, including industrial facilities, commercial complexes, and residential buildings. Their versatility allows them to meet the diverse needs of various construction projects. Furthermore, architectural film panels are cost-effective and easy to use. Compared to traditional formwork materials, it offers significant advantages in terms of cost, construction efficiency, and service life. Therefore, it has become the preferred material for many contractors seeking efficient and reliable formwork solutions, providing strong support for the smooth implementation of various construction projects.

IV. Advantages of Architectural Film Faced Boards

4.1 Enhanced Durability and Service Life

Architectural film face boards exhibit exceptional durability through the perfect combination of a high-quality base material and a durable cover. The high-quality base material provides a stable structural foundation for the board, while the durable cover effectively protects the base material from environmental corrosion and damage. In practice, this combination enables architectural film face boards to withstand repeated use and various harsh environments, resulting in a long service life. Compared to traditional formwork materials, architectural film face boards require less frequent replacement, reducing formwork material costs and construction interruptions caused by formwork replacement, thereby improving project continuity and efficiency.

4.2 Comprehensive Performance Benefits Efficient Construction and Improved Quality

The multiple superior properties of architectural film face boards work together to significantly improve construction efficiency and effectively safeguard building quality. Its high strength enables formwork to withstand heavy loads, reducing the need for formwork support systems, streamlining the construction process, and accelerating construction progress. Its superior surface finish ensures a high-quality concrete surface, reducing the workload and time required for subsequent surface treatment. Its reliable fire and chemical resistance ensures the long-term safety of buildings and reduces ongoing maintenance costs. These combined advantages enable building membrane panels to improve construction efficiency while effectively enhancing the overall quality of buildings, making a positive contribution to the sustainable development of the construction industry.

Building membrane panels, with their unique properties, wide range of applications, and significant advantages, occupy a vital position in modern construction. They not only provide a reliable and efficient solution for concrete forming, but also play a key role in improving building quality, construction efficiency, and economic benefits. With the continuous development of the construction industry and the increasing demands on building material performance, building membrane panels are expected to be widely used in more fields due to their continuous innovation and optimization, injecting new vitality into the progress and development of the construction industry. In the future, the research and application of architectural film faced panels will continue to deepen and further tap their potential to meet the ever-changing needs of the construction market and contribute to creating a higher-quality, more efficient and safer building environment.

Building membrane panels, with their unique properties, wide range of applications, and significant advantages, occupy a vital position in modern construction. They not only provide a reliable and efficient solution for concrete forming, but also play a key role in improving building quality, construction efficiency, and economic benefits. With the continuous development of the construction industry and the increasing demands on building material performance, building membrane panels are expected to be widely used in more fields due to their continuous innovation and optimization, injecting new vitality into the progress and development of the construction industry. In the future, the research and application of architectural film faced panels will continue to deepen and further tap their potential to meet the ever-changing needs of the construction market and contribute to creating a higher-quality, more efficient and safer building environment.

In modern construction, with increasing demands for building quality, construction efficiency, and environmental protection, the research and application of new building materials has become increasingly critical. As an innovative building material, building film faced panels, with their unique performance advantages, have rapidly become an indispensable component in the concrete forming process. They are widely used in various projects, including high-rise buildings, bridges, and tunnels, providing strong support for the development of modern architecture. This article will comprehensively and in-depth analyze the characteristics, applications, and significant advantages of building film faced panels, aiming to provide a comprehensive and practical reference for those involved in the construction industry.

II. Characteristics of Building Film Faced Panels

2.1 Material Composition and Careful Screening

The performance of building film faced panels is fundamentally based on their high-quality base material. Due to differences in climate and wood resources between northern and southern my country, material selection is tailored to local conditions. Northern China often uses high-quality birch and poplar, while southern China prefers pine and eucalyptus. These woods undergo a rigorous and meticulous screening process before being used. The screening criteria are extremely stringent, requiring the wood to be scar-free, crack-free, uniform in density, and possess high bending strength. This rigorous screening ensures that each substrate is of exceptional quality, laying a solid foundation for subsequent coating adhesion and overall board performance stability, effectively enhancing the durability and overall performance of the film-faced panels.

2.2 Excellent Surface Finish and Precision

The film-faced panels utilize a meticulously polished surface treatment process, achieving a mirror-like finish with a flatness tolerance of ≤0.02 mm/m. This high-precision surface treatment is crucial in many ways. During the demolding process, the smooth surface provides an ideal interface for concrete separation, significantly simplifying demolding and ensuring a smooth and complete separation of the concrete surface from the formwork. Furthermore, this high-quality demolding ensures an exceptionally smooth concrete surface, reducing the workload and cost of subsequent surface treatment. Furthermore, the smooth surface improves construction efficiency, reduces delays caused by formwork surface defects, and accelerates project progress.

2.3 Excellent Mechanical Properties

Mechanical properties are one of the core advantages of architectural film facing panels. Its static flexural strength is exceptional, more than twice that of ordinary wood, providing a strong load-bearing capacity. In actual engineering applications, it can easily withstand lateral concrete pressures of up to 60 kN/m². This characteristic makes architectural film facing panels irreplaceable in the construction of key structural components of high-rise buildings, such as shear walls, beams, and columns. In these structures subjected to heavy loads, architectural film facing panels maintain stability and provide reliable support, ensuring the safety and stability of the building and effectively resisting various external forces.

2.4 Reliable Fire and Chemical Resistance

Architectural film facing panels offer excellent safety and protection. Their covering layer achieves a B1 fire rating, a significant fire resistance performance in the field of building safety. In the event of a fire, they effectively slow the spread of fire, buying valuable time for evacuation and rescue efforts, and significantly reducing damage to the building and its residents. This fire resistance is particularly critical in high-rise buildings and those with complex structures. Furthermore, the phenolic resin adhesive layer in building film panels plays a crucial role in chemical protection. It acts as a solid barrier, effectively isolating moisture and chemicals, preventing these harmful substances from corroding and contaminating the concrete. This extends the service life of the formwork, reduces the need for frequent replacement and maintenance due to formwork damage, and lowers project costs.

III. Applications of Building Film Panels

3.1 High-Rise Building Construction

Building film panels play a vital role in high-rise building projects. Their high strength and excellent surface finish make them an ideal choice for forming key structural components such as shear walls, beams, and columns. During the concrete pouring process, building film panels can withstand the immense pressure of concrete, ensuring that the formwork remains stable during the pouring and curing phases, preventing deformation or damage due to excessive pressure. This stability ensures the dimensional accuracy and surface quality of the concrete components, resulting in high-quality concrete components that meet stringent standards and provide a solid foundation for the overall quality of high-rise buildings. Furthermore, their efficient construction performance helps shorten the construction period of high-rise buildings and improve project efficiency.

3.2 Bridge and Tunnel Construction

Bridge and tunnel construction places extremely stringent demands on formwork materials, requiring high strength, durability, and excellent environmental adaptability. Architectural film panels, with their superior mechanical properties and exceptional resistance to environmental factors, perfectly meet these requirements. During bridge construction, bridge structures are exposed to the elements for extended periods, facing multiple challenges such as moisture, chemical corrosion, and fire hazards. The fire and chemical resistance of architectural film panels effectively address these challenges, protecting the safety and durability of bridge structures. Tunnel construction, characterized by relatively confined construction space, places high demands on concrete surface quality. The smooth surface finish of architectural film panels facilitates demoulding, significantly reducing the risk of concrete surface defects such as honeycombing and roughness, thereby improving the quality and aesthetics of tunnel construction.

3.3 Other Construction Projects

In addition to large-scale projects such as high-rise buildings, bridges, and tunnels, architectural film panels are widely used in various construction projects, including industrial facilities, commercial complexes, and residential buildings. Their versatility allows them to meet the diverse needs of various construction projects. Furthermore, architectural film panels are cost-effective and easy to use. Compared to traditional formwork materials, it offers significant advantages in terms of cost, construction efficiency, and service life. Therefore, it has become the preferred material for many contractors seeking efficient and reliable formwork solutions, providing strong support for the smooth implementation of various construction projects.

IV. Advantages of Architectural Film Faced Boards

4.1 Enhanced Durability and Service Life

Architectural film face boards exhibit exceptional durability through the perfect combination of a high-quality base material and a durable cover. The high-quality base material provides a stable structural foundation for the board, while the durable cover effectively protects the base material from environmental corrosion and damage. In practice, this combination enables architectural film face boards to withstand repeated use and various harsh environments, resulting in a long service life. Compared to traditional formwork materials, architectural film face boards require less frequent replacement, reducing formwork material costs and construction interruptions caused by formwork replacement, thereby improving project continuity and efficiency.

4.2 Comprehensive Performance Benefits Efficient Construction and Improved Quality

The multiple superior properties of architectural film face boards work together to significantly improve construction efficiency and effectively safeguard building quality. Its high strength enables formwork to withstand heavy loads, reducing the need for formwork support systems, streamlining the construction process, and accelerating construction progress. Its superior surface finish ensures a high-quality concrete surface, reducing the workload and time required for subsequent surface treatment. Its reliable fire and chemical resistance ensures the long-term safety of buildings and reduces ongoing maintenance costs. These combined advantages enable building membrane panels to improve construction efficiency while effectively enhancing the overall quality of buildings, making a positive contribution to the sustainable development of the construction industry.