How well do building film-faced panels perform in humid environments?

Release Time : 2025-10-22

The water resistance of film-faced panels in humid environments is one of their core properties, directly determining their application value in high-humidity environments such as underground construction, bathrooms, and kitchens. This panel, through a surface coating process, is tightly bonded to the substrate, creating a multi-layered waterproof barrier that effectively resists water penetration and exhibits water resistance far exceeding that of traditional wood.

The surface coating of film-faced panels is crucial to their water resistance. This film, typically made from polymer materials such as phenolic resin, melamine, or PVC, has a dense molecular structure that completely blocks direct contact between moisture and the substrate. In humid environments, water droplets formed on the film's surface slide off quickly due to its hydrophobic nature, avoiding retention on the panel surface and preventing moisture from penetrating through capillary action. Even after prolonged exposure to humid air, the film maintains stable physical properties and resists swelling or deformation due to moisture absorption.

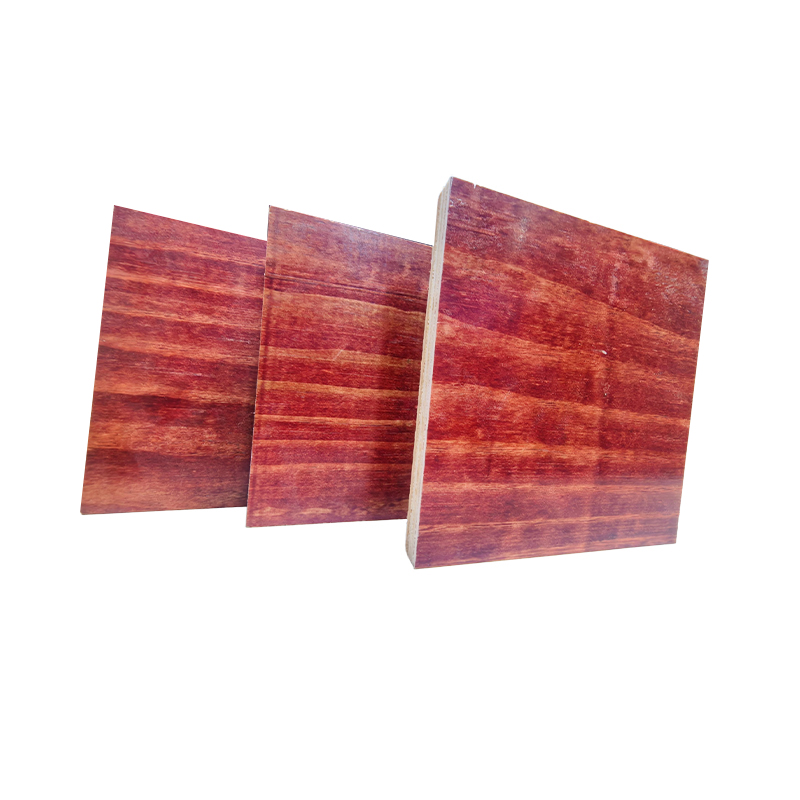

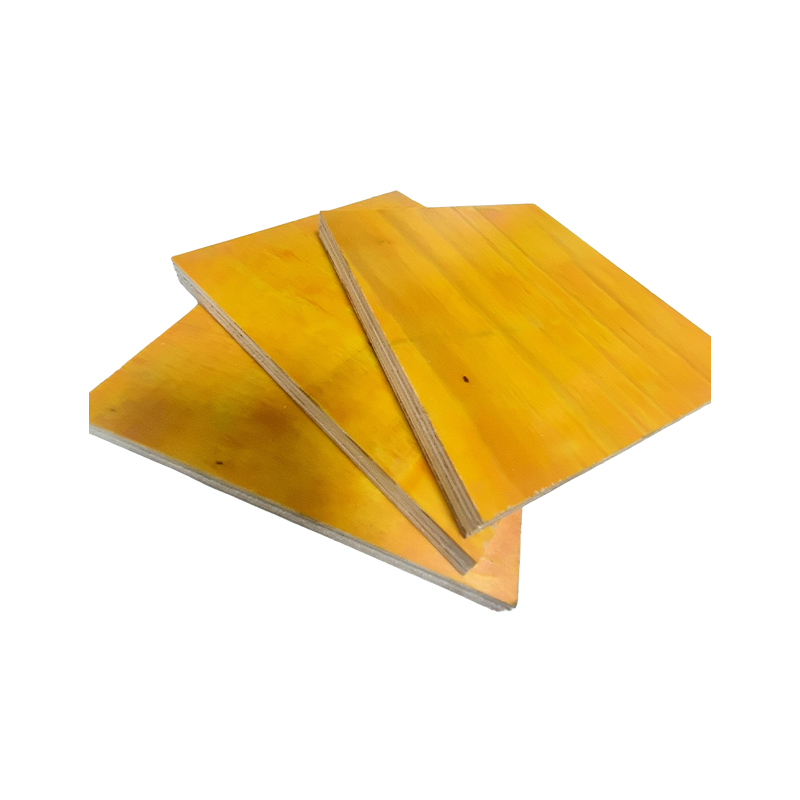

The choice and treatment of the substrate plays a decisive role in the water resistance of film-faced panels. High-quality building film-faced panels are often made from imported hardwoods such as pine and eucalyptus. These woods have low inherent water absorption, and after high-temperature and high-pressure treatment, their fiber structure becomes more compact, further reducing pathways for moisture penetration. During the manufacturing process, the base and film layers are heat-pressed together using a specialized waterproof adhesive. This adhesive not only fills the tiny pores in the wood surface but also forms a chemical bond, ensuring a seamless bond between the film and base. Even after prolonged immersion in water, the panels will not delaminate or delaminate.

Edge treatment of building film-faced panels is also crucial for enhancing water resistance. Cutting the edges of traditional panels exposes untreated wood fibers, creating a vulnerable opening for moisture penetration. However, building film-faced panels are sealed during production, using methods such as waterproof paint or metal stripping, to create a complete, waterproof seal. This design prevents moisture absorption from degrading the overall performance of the panels when used in humid environments.

In practical applications, the water resistance of building film-faced panels is also reflected in their compatibility with concrete pouring. During construction, formwork must withstand the lateral pressure and moisture of concrete. Ordinary wood easily deforms due to moisture absorption during this process, resulting in uneven concrete surfaces. However, the smooth and water-resistant surface of film-faced panels ensures a smooth finish after concrete forming, eliminating the need for secondary polishing and significantly improving construction efficiency. Furthermore, their stable size and shape ensure the formwork's reusability, reducing project costs.

The impact of long-term humid environments on film-faced panels primarily stems from potential changes in the substrate. Although the film effectively blocks moisture, prolonged exposure to high humidity can still cause the fibers to slowly swell due to minute moisture penetration. However, high-quality film-faced panels minimize this effect by using a low-water-absorption substrate and optimizing the adhesive formula. In practice, as long as ventilation is maintained and prolonged water accumulation is avoided, film-faced panels are fully capable of withstanding long-term use in humid environments.

From an environmental and health perspective, the water resistance of film-faced panels offers additional advantages. Because they are less likely to absorb moisture, they do not harbor mold, effectively preventing the mold problem common in humid environments. This is especially important for places that need to maintain hygiene standards, such as hospital operating rooms, food processing plants, etc. At the same time, the release of harmful substances is strictly controlled during the production process of high-quality building film faced panels, ensuring indoor air quality and meeting the green and environmental protection requirements of modern buildings.