How does Building Formwork Gold Board improve assembly efficiency and precision through modular design?

Release Time : 2025-11-05

In the construction of modern super high-rise buildings and complex public facilities, the core tube and irregular structures place extremely high demands on the adaptability, installation speed, and forming precision of the formwork system. Traditional wooden formwork has many seams and is prone to deformation, while aluminum formwork, although highly precise, is expensive and lacks flexibility. Building Formwork Gold Board, with its aerospace-grade materials, integrated structure, and highly modular system design, demonstrates superior construction advantages under complex working conditions, significantly improving assembly efficiency and concrete forming precision.

1. Aerospace-grade materials and integrated structure lay the foundation for high precision

Building Formwork Gold Board uses 6061-T6 aerospace-grade aluminum alloy as its core material, combining high strength and lightweight characteristics. The weight of a single formwork piece is more than 40% lighter than traditional steel formwork, facilitating manual handling at heights and rapid positioning. Its vertical stiffeners and side frame stiffeners are produced using a one-time extrusion molding process, significantly reducing welding joints. This not only avoids dimensional errors caused by weld deformation but also improves overall rigidity and bending resistance. Double-layer surface curing treatment forms a dense protective layer on the template surface, ensuring no deformation or corrosion during long-term use and guaranteeing high-precision repeated use.

2. Modular System Enables Rapid Assembly and Flexible Adaptation

This template system consists of four main modules: templates, supports, fasteners, and accessories. Each component uses a standardized interface design, allowing for rapid assembly like "building blocks." During core tube construction, prefabricated modules such as standard wall panels, corner panels, and opening panels can be pre-assembled according to drawings, requiring only bolts or pins for on-site connection, significantly shortening formwork time. For irregular structures, the system supports customized template units—precisely cutting curved edges or bevels through CNC machining, combined with specialized adapters, to achieve seamless splicing of complex geometric shapes. This "factory prefabrication + on-site rapid assembly" model compresses the traditional formwork work that takes several days to just a few hours, significantly improving the construction pace.

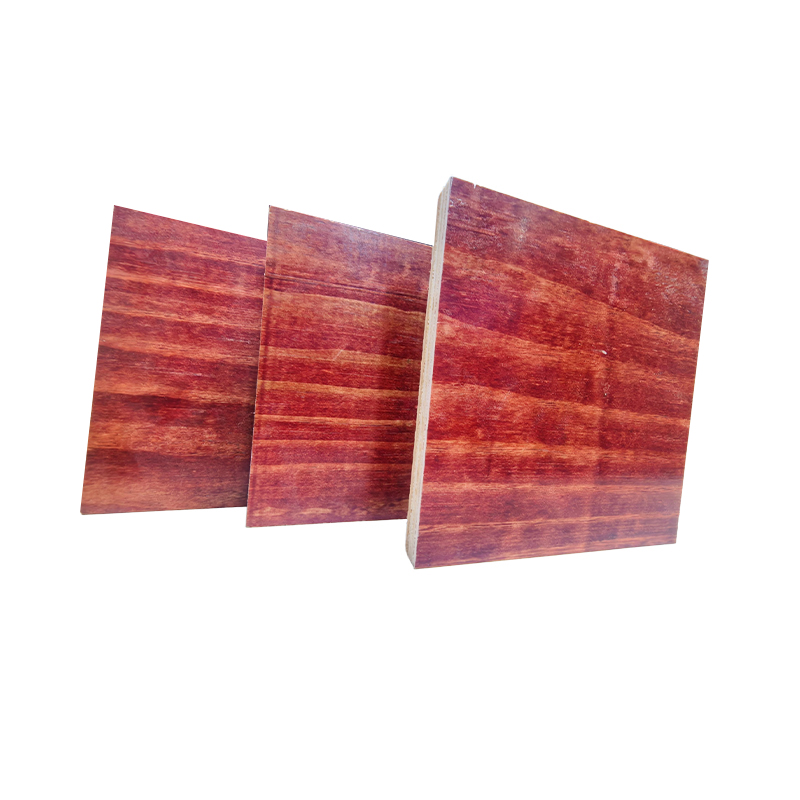

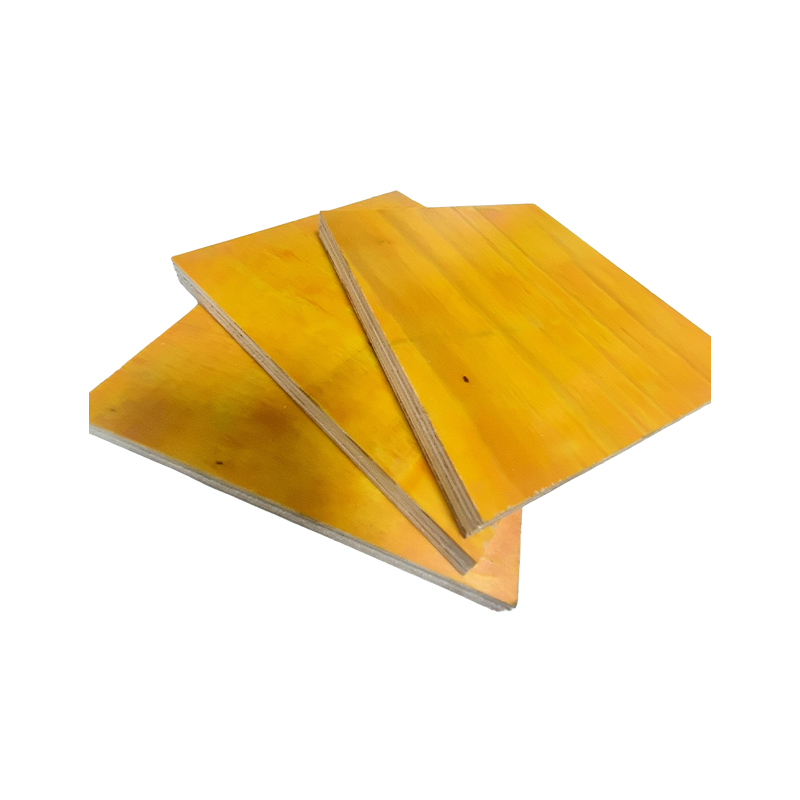

3. Composite Core Material and Smooth Surface Ensure High-Quality Concrete Forming

The formwork core material is made of high-quality wood such as poplar and pine, composited with high-temperature, high-pressure, and high-strength impregnated film paper, combining lightweight with high compressive strength. The smooth and dense surface ensures a mirror-like finish on the concrete wall after demolding, requiring almost no secondary plastering, making it particularly suitable for fair-faced concrete or projects delivered with high-end finishes. In areas with dense reinforcement in the core tube, the formwork's high abrasion resistance resists reinforcement scratches, preventing surface damage that could affect aesthetics. Furthermore, customizable thicknesses and dimensions meet the requirements of different wall loads and floor heights, achieving precise matching of "one solution per project."

4. System Collaboration Ensures Stable and Reliable Pouring Process

During concrete pouring, the modular formwork system forms an integrated load-bearing structure through a high-rigidity frame and dedicated support system, effectively resisting lateral pressure and eliminating the risks of formwork bulging and displacement. The fasteners employ a self-locking design, ensuring joint gaps are less than 1 mm, preventing grout leakage and the formation of a "honeycomb surface." Even during continuous casting of core tubes for super high-rise buildings exceeding 300 meters, the system maintains geometrical stability, ensuring verticality and flatness meet millimeter-level acceptance standards.

Building Formwork Gold Board, through triple innovation in materials, structure, and system, deeply integrates modular concepts into the construction of complex structures. It not only solves industry pain points such as difficult formwork, low precision, and slow efficiency in irregularly shaped parts, but also propels building industrialization to a higher level with its customizable, repeatable, and high-quality molding advantages. In contemporary engineering construction that prioritizes both speed and quality, Gold Board is becoming a reliable and efficient solution for the construction of high-rise core tubes and irregularly shaped structures.

1. Aerospace-grade materials and integrated structure lay the foundation for high precision

Building Formwork Gold Board uses 6061-T6 aerospace-grade aluminum alloy as its core material, combining high strength and lightweight characteristics. The weight of a single formwork piece is more than 40% lighter than traditional steel formwork, facilitating manual handling at heights and rapid positioning. Its vertical stiffeners and side frame stiffeners are produced using a one-time extrusion molding process, significantly reducing welding joints. This not only avoids dimensional errors caused by weld deformation but also improves overall rigidity and bending resistance. Double-layer surface curing treatment forms a dense protective layer on the template surface, ensuring no deformation or corrosion during long-term use and guaranteeing high-precision repeated use.

2. Modular System Enables Rapid Assembly and Flexible Adaptation

This template system consists of four main modules: templates, supports, fasteners, and accessories. Each component uses a standardized interface design, allowing for rapid assembly like "building blocks." During core tube construction, prefabricated modules such as standard wall panels, corner panels, and opening panels can be pre-assembled according to drawings, requiring only bolts or pins for on-site connection, significantly shortening formwork time. For irregular structures, the system supports customized template units—precisely cutting curved edges or bevels through CNC machining, combined with specialized adapters, to achieve seamless splicing of complex geometric shapes. This "factory prefabrication + on-site rapid assembly" model compresses the traditional formwork work that takes several days to just a few hours, significantly improving the construction pace.

3. Composite Core Material and Smooth Surface Ensure High-Quality Concrete Forming

The formwork core material is made of high-quality wood such as poplar and pine, composited with high-temperature, high-pressure, and high-strength impregnated film paper, combining lightweight with high compressive strength. The smooth and dense surface ensures a mirror-like finish on the concrete wall after demolding, requiring almost no secondary plastering, making it particularly suitable for fair-faced concrete or projects delivered with high-end finishes. In areas with dense reinforcement in the core tube, the formwork's high abrasion resistance resists reinforcement scratches, preventing surface damage that could affect aesthetics. Furthermore, customizable thicknesses and dimensions meet the requirements of different wall loads and floor heights, achieving precise matching of "one solution per project."

4. System Collaboration Ensures Stable and Reliable Pouring Process

During concrete pouring, the modular formwork system forms an integrated load-bearing structure through a high-rigidity frame and dedicated support system, effectively resisting lateral pressure and eliminating the risks of formwork bulging and displacement. The fasteners employ a self-locking design, ensuring joint gaps are less than 1 mm, preventing grout leakage and the formation of a "honeycomb surface." Even during continuous casting of core tubes for super high-rise buildings exceeding 300 meters, the system maintains geometrical stability, ensuring verticality and flatness meet millimeter-level acceptance standards.

Building Formwork Gold Board, through triple innovation in materials, structure, and system, deeply integrates modular concepts into the construction of complex structures. It not only solves industry pain points such as difficult formwork, low precision, and slow efficiency in irregularly shaped parts, but also propels building industrialization to a higher level with its customizable, repeatable, and high-quality molding advantages. In contemporary engineering construction that prioritizes both speed and quality, Gold Board is becoming a reliable and efficient solution for the construction of high-rise core tubes and irregularly shaped structures.