How does Building Formwork Gold Board maintain its color even after repeated use?

Release Time : 2025-11-20

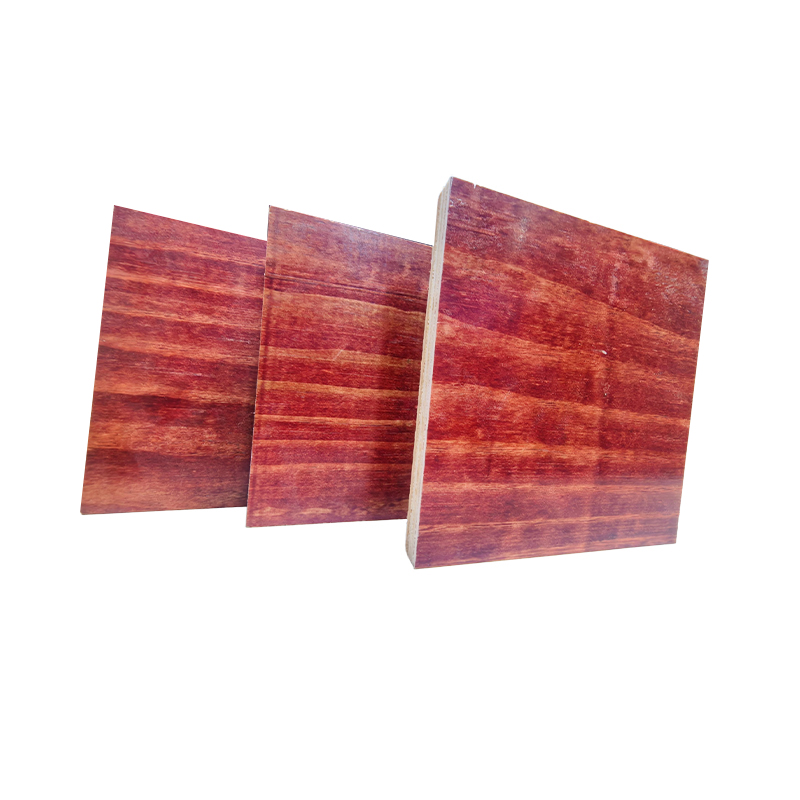

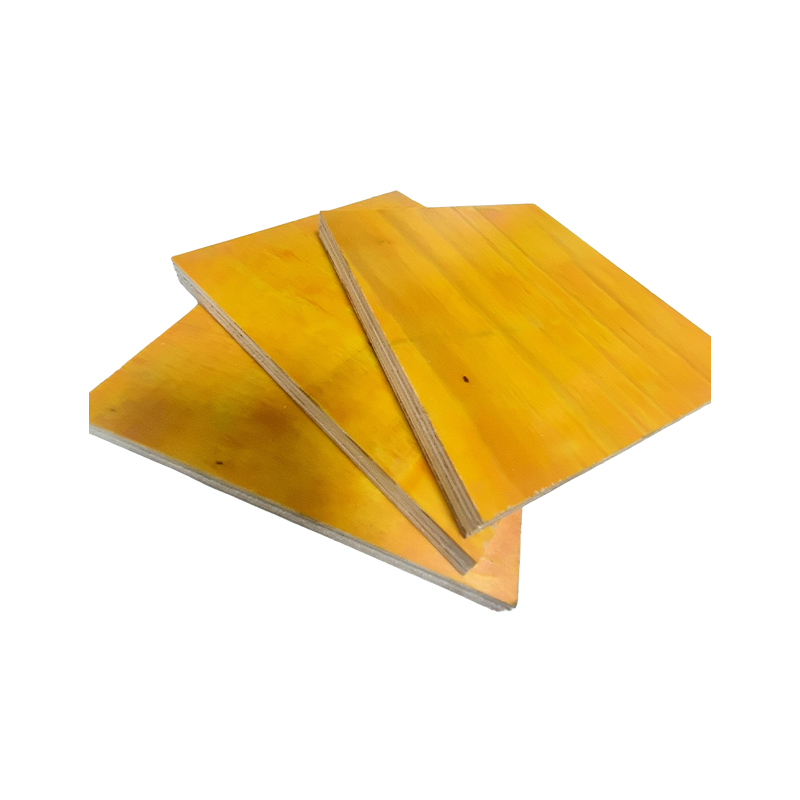

In modern construction engineering, Building Formwork Gold Board is not only the "mold" for concrete forming, but also a key component determining the structural appearance quality and construction efficiency. Traditional wooden formwork often suffers from problems such as surface peeling, water absorption and swelling, and numerous scratches after a few uses, leading to pitted concrete surfaces, air pockets, and even grout leakage. However, Building Formwork Gold Board, thanks to its unique material structure and advanced technology, maintains a smooth, new-looking surface and uniform, stable color even after dozens or even hundreds of high-intensity uses, truly achieving "color retention." This outstanding performance stems from its systematic design from core material to surface layer.

1. Double-Layer Curing: Constructing a Dense Protective Barrier

The core anti-wear secret of Building Formwork Gold Board lies in its double-layer surface curing process. Based on a high-quality poplar or pine core material, a high-strength phenolic resin impregnated film paper is applied to the surface, followed by a high-temperature, high-pressure hot-pressing process. This process not only fully cross-links and cures the resin, but also forms two dense protective layers on the template surface: the outer layer is a highly cross-linked, wear-resistant film with excellent scratch and impact resistance; the inner layer deeply penetrates the wood fibers, enhancing interfacial bonding and preventing delamination or bulging caused by moisture intrusion. This double-layer structure acts like "armor" for the wood, effectively resisting scratches during rebar tying, high-frequency impacts from vibrators, and mechanical friction during demolding. Even after dozens of disassemblies and reassemblies, the surface remains smooth and flat, without obvious scratches or peeling.

2. High-Quality Core Material + Integrated Reinforcing Ribs: Ensuring Dimensional Stability from the Inside

The "non-deformation" of the gold-plated board is a prerequisite for "non-discoloration." If the template expands due to moisture absorption or bends under pressure, the surface protective layer is prone to cracking, thus accelerating aging. Therefore, the gold-plated board uses poplar or pine wood with a moisture content strictly controlled between 8% and 12% as the core material. This wood has straight grain, uniform density, low internal stress after hot pressing, and high dimensional stability. Meanwhile, the vertical reinforcing ribs and side frame reinforcing ribs are manufactured using a one-time molding technology, eliminating the need for subsequent welding or nailing. This completely eliminates the edge warping problems caused by weld corrosion or loose connections in traditional metal frames. The overall structure is highly rigid and not easily deformed under the lateral pressure of concrete, ensuring that the formwork returns to its original shape after each pour and avoiding surface damage caused by the accumulation of minor deformations.

3. Smooth Surface: Reduced Adhesion, Extended Lifespan

After high-temperature and high-pressure treatment, the surface roughness Ra of the gold plate can be controlled below 6.3μm, approaching a mirror finish. This high gloss not only makes demolding smoother and significantly reduces the amount of release agent used, but more importantly, it greatly reduces the adhesion of concrete slurry to the formwork surface. There is almost no residue after demolding; simple rinsing is all that's needed for reuse, avoiding damage to the surface from strong scrapers. Furthermore, the dense resin layer has excellent alkali resistance, resisting the high pH environment generated during cement hydration for a long time, preventing whitening, powdering, and other phenomena, and maintaining its original color and texture.

4. System Collaboration: Ensuring Turnover Performance Across the Entire Chain

Gold Board is not used in isolation, but rather as part of a four-in-one system encompassing formwork, support, fastening, and accessories. Scientifically spaced supports and reliable fastening methods effectively distribute loads, preventing indentations or dents caused by localized overload; standardized accessories ensure precise installation each time, reducing damage from human error. This systemic approach further extends the service life of the Gold Board from the usage stage.

The fact that Building Formwork Gold Board remains unchanged even after repeated use is no accident, but rather the result of the combined efforts of materials science, process innovation, and systems engineering. It perfectly blends the lightweight and renewable advantages of natural wood with the durability and stability of synthetic resin, creating an environmentally friendly and highly efficient green building material. In today's pursuit of high-quality construction and sustainable development, Gold Board not only enhances the quality of concrete finishes but also provides a practical solution for the construction industry to reduce costs, increase efficiency, and minimize resource waste through its durability of hundreds of reuses.

1. Double-Layer Curing: Constructing a Dense Protective Barrier

The core anti-wear secret of Building Formwork Gold Board lies in its double-layer surface curing process. Based on a high-quality poplar or pine core material, a high-strength phenolic resin impregnated film paper is applied to the surface, followed by a high-temperature, high-pressure hot-pressing process. This process not only fully cross-links and cures the resin, but also forms two dense protective layers on the template surface: the outer layer is a highly cross-linked, wear-resistant film with excellent scratch and impact resistance; the inner layer deeply penetrates the wood fibers, enhancing interfacial bonding and preventing delamination or bulging caused by moisture intrusion. This double-layer structure acts like "armor" for the wood, effectively resisting scratches during rebar tying, high-frequency impacts from vibrators, and mechanical friction during demolding. Even after dozens of disassemblies and reassemblies, the surface remains smooth and flat, without obvious scratches or peeling.

2. High-Quality Core Material + Integrated Reinforcing Ribs: Ensuring Dimensional Stability from the Inside

The "non-deformation" of the gold-plated board is a prerequisite for "non-discoloration." If the template expands due to moisture absorption or bends under pressure, the surface protective layer is prone to cracking, thus accelerating aging. Therefore, the gold-plated board uses poplar or pine wood with a moisture content strictly controlled between 8% and 12% as the core material. This wood has straight grain, uniform density, low internal stress after hot pressing, and high dimensional stability. Meanwhile, the vertical reinforcing ribs and side frame reinforcing ribs are manufactured using a one-time molding technology, eliminating the need for subsequent welding or nailing. This completely eliminates the edge warping problems caused by weld corrosion or loose connections in traditional metal frames. The overall structure is highly rigid and not easily deformed under the lateral pressure of concrete, ensuring that the formwork returns to its original shape after each pour and avoiding surface damage caused by the accumulation of minor deformations.

3. Smooth Surface: Reduced Adhesion, Extended Lifespan

After high-temperature and high-pressure treatment, the surface roughness Ra of the gold plate can be controlled below 6.3μm, approaching a mirror finish. This high gloss not only makes demolding smoother and significantly reduces the amount of release agent used, but more importantly, it greatly reduces the adhesion of concrete slurry to the formwork surface. There is almost no residue after demolding; simple rinsing is all that's needed for reuse, avoiding damage to the surface from strong scrapers. Furthermore, the dense resin layer has excellent alkali resistance, resisting the high pH environment generated during cement hydration for a long time, preventing whitening, powdering, and other phenomena, and maintaining its original color and texture.

4. System Collaboration: Ensuring Turnover Performance Across the Entire Chain

Gold Board is not used in isolation, but rather as part of a four-in-one system encompassing formwork, support, fastening, and accessories. Scientifically spaced supports and reliable fastening methods effectively distribute loads, preventing indentations or dents caused by localized overload; standardized accessories ensure precise installation each time, reducing damage from human error. This systemic approach further extends the service life of the Gold Board from the usage stage.

The fact that Building Formwork Gold Board remains unchanged even after repeated use is no accident, but rather the result of the combined efforts of materials science, process innovation, and systems engineering. It perfectly blends the lightweight and renewable advantages of natural wood with the durability and stability of synthetic resin, creating an environmentally friendly and highly efficient green building material. In today's pursuit of high-quality construction and sustainable development, Gold Board not only enhances the quality of concrete finishes but also provides a practical solution for the construction industry to reduce costs, increase efficiency, and minimize resource waste through its durability of hundreds of reuses.