Why does the surface film of building film faced panels significantly improve the surface smoothness of concrete after demolding?

Release Time : 2025-12-03

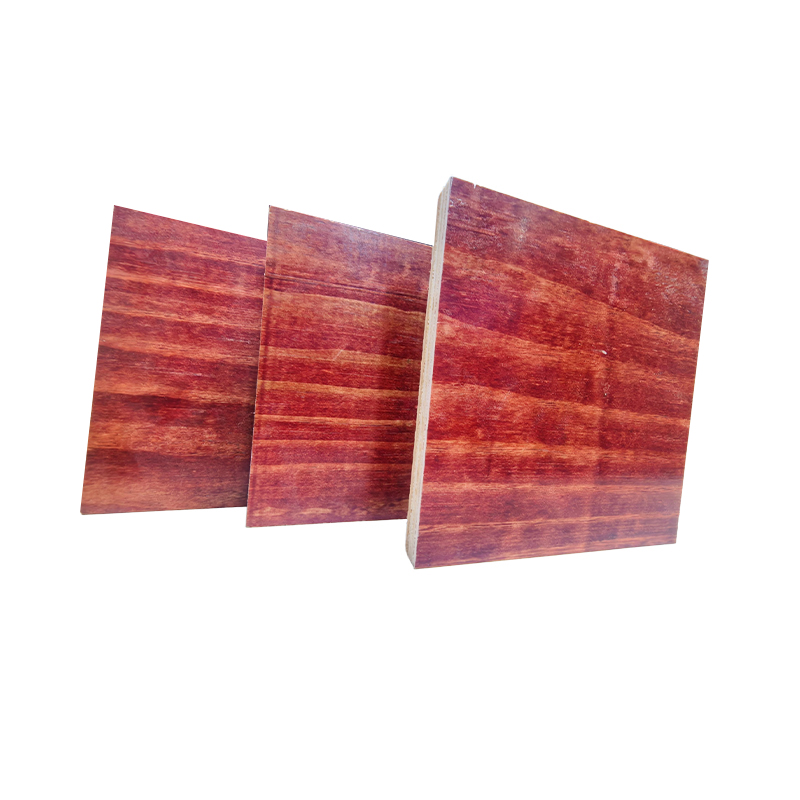

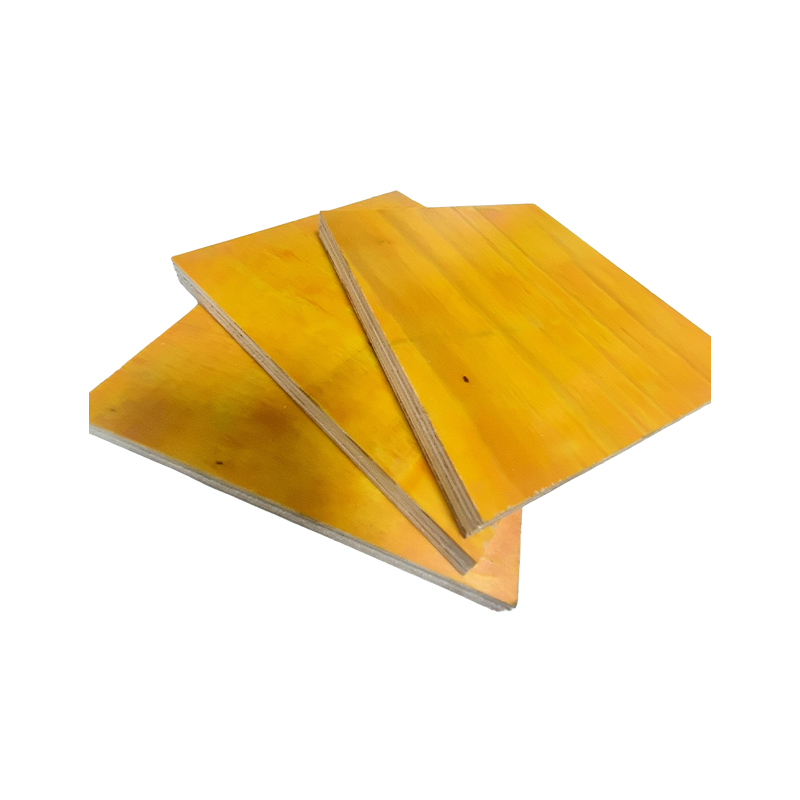

Building film faced panels, as a key material in modern concrete construction, are widely used in high-rise buildings, bridges, tunnels, and other projects with high requirements for concrete surface quality due to their excellent molding performance and high turnover rate. One of their most notable advantages is that they can achieve a near-mirror-like smoothness on the concrete surface after demolding, greatly reducing the need for subsequent grinding or repair. This superior performance is mainly attributed to the high-strength impregnated film paper covering the surface and its synergistic effect with the substrate.

1. Dense and Smooth Physical Barrier

The film on the surface of the film-faced panels is typically made of special paper impregnated with melamine or phenolic resin, cured under high temperature and pressure to form a continuous, non-porous, highly cross-linked polymer film. This film has extremely low surface roughness, far superior to ordinary wooden formwork or uncoated plywood. 1. **During concrete pouring:** This dense structure effectively prevents cement slurry from penetrating into the formwork, avoiding pitting, porosity, or color variations caused by uneven moisture loss or fine aggregate embedding in the formwork surface. This ensures a smooth and uniform concrete surface.

2. Excellent Demolding Performance:

Traditional wooden formwork often becomes difficult to demold after contact with concrete due to water absorption and expansion or chemical adhesion. Forced demolding can easily damage the concrete surface. The resin film of the laminated board has extremely low surface energy and good hydrophobicity, almost completely avoiding chemical reactions with cement hydration products. Simultaneously, its high surface hardness and low coefficient of friction enable a "self-demolding" effect—the concrete naturally separates from the formwork without leaving residue or slurry residue, significantly improving demolding efficiency and finished product quality.

3. Alkali and Corrosion Resistance Ensures Long-Term Smoothness:

Concrete is highly alkaline. Ordinary wood or coatings are easily corroded, fuzzed, or peeled after repeated use, resulting in a rough surface in subsequent pours. The melamine-formaldehyde resin or modified phenolic resin used in laminated panels possesses excellent alkali resistance and chemical stability. Even after repeated exposure to highly alkaline environments, the film maintains its structural integrity and smooth surface. This means that even after ten or even dozens of uses, the laminated panel can still provide a consistently high-quality finished surface.

4. Synergistic Support Between Substrate and Film

The superior performance of laminated panels depends not only on the surface film but also on the support of a high-quality substrate. Birch and poplar are commonly used in northern regions, while pine and eucalyptus are preferred in the south. All boards undergo rigorous selection to ensure they are free of scars and cracks, have uniform density, and high bending strength. This highly stable substrate is not easily deformed under stress, providing a flat and firm adhesion base for the film. If the substrate itself has unevenness or warping, even a smooth film cannot guarantee the flatness of the concrete surface. Therefore, the balance of rigidity and flexibility between the substrate and the film is key to achieving a high gloss finish.

5. Process Control Ensures Surface Consistency

During manufacturing, the film-faced panels are pressed under high temperature and pressure conditions of 130–150℃ and 8–15 MPa, allowing the resin to fully flow, cure, and bond tightly to the substrate. This process not only eliminates micro-wrinkles or bubbles on the film surface but also ensures that the thickness tolerance of the entire panel is controlled within ±0.2mm. Such precise manufacturing standards ensure that each film-faced panel provides a highly consistent molding effect, meeting the stringent surface quality requirements of high-standard projects such as fair-faced concrete.

In summary, the reason why building film faced panels significantly improve the surface smoothness of concrete after demolding is the result of the combined effects of their dense and smooth resin film, excellent demolding properties, alkali resistance, high-quality substrate support, and precision manufacturing process. It not only improves construction efficiency but also promotes the development of modern architecture towards a high-quality direction of "no plastering, no decoration," becoming an indispensable core material for green building and industrialized construction.

1. Dense and Smooth Physical Barrier

The film on the surface of the film-faced panels is typically made of special paper impregnated with melamine or phenolic resin, cured under high temperature and pressure to form a continuous, non-porous, highly cross-linked polymer film. This film has extremely low surface roughness, far superior to ordinary wooden formwork or uncoated plywood. 1. **During concrete pouring:** This dense structure effectively prevents cement slurry from penetrating into the formwork, avoiding pitting, porosity, or color variations caused by uneven moisture loss or fine aggregate embedding in the formwork surface. This ensures a smooth and uniform concrete surface.

2. Excellent Demolding Performance:

Traditional wooden formwork often becomes difficult to demold after contact with concrete due to water absorption and expansion or chemical adhesion. Forced demolding can easily damage the concrete surface. The resin film of the laminated board has extremely low surface energy and good hydrophobicity, almost completely avoiding chemical reactions with cement hydration products. Simultaneously, its high surface hardness and low coefficient of friction enable a "self-demolding" effect—the concrete naturally separates from the formwork without leaving residue or slurry residue, significantly improving demolding efficiency and finished product quality.

3. Alkali and Corrosion Resistance Ensures Long-Term Smoothness:

Concrete is highly alkaline. Ordinary wood or coatings are easily corroded, fuzzed, or peeled after repeated use, resulting in a rough surface in subsequent pours. The melamine-formaldehyde resin or modified phenolic resin used in laminated panels possesses excellent alkali resistance and chemical stability. Even after repeated exposure to highly alkaline environments, the film maintains its structural integrity and smooth surface. This means that even after ten or even dozens of uses, the laminated panel can still provide a consistently high-quality finished surface.

4. Synergistic Support Between Substrate and Film

The superior performance of laminated panels depends not only on the surface film but also on the support of a high-quality substrate. Birch and poplar are commonly used in northern regions, while pine and eucalyptus are preferred in the south. All boards undergo rigorous selection to ensure they are free of scars and cracks, have uniform density, and high bending strength. This highly stable substrate is not easily deformed under stress, providing a flat and firm adhesion base for the film. If the substrate itself has unevenness or warping, even a smooth film cannot guarantee the flatness of the concrete surface. Therefore, the balance of rigidity and flexibility between the substrate and the film is key to achieving a high gloss finish.

5. Process Control Ensures Surface Consistency

During manufacturing, the film-faced panels are pressed under high temperature and pressure conditions of 130–150℃ and 8–15 MPa, allowing the resin to fully flow, cure, and bond tightly to the substrate. This process not only eliminates micro-wrinkles or bubbles on the film surface but also ensures that the thickness tolerance of the entire panel is controlled within ±0.2mm. Such precise manufacturing standards ensure that each film-faced panel provides a highly consistent molding effect, meeting the stringent surface quality requirements of high-standard projects such as fair-faced concrete.

In summary, the reason why building film faced panels significantly improve the surface smoothness of concrete after demolding is the result of the combined effects of their dense and smooth resin film, excellent demolding properties, alkali resistance, high-quality substrate support, and precision manufacturing process. It not only improves construction efficiency but also promotes the development of modern architecture towards a high-quality direction of "no plastering, no decoration," becoming an indispensable core material for green building and industrialized construction.