Why does building red board maintain good flatness and strength even after multiple uses?

Release Time : 2025-12-17

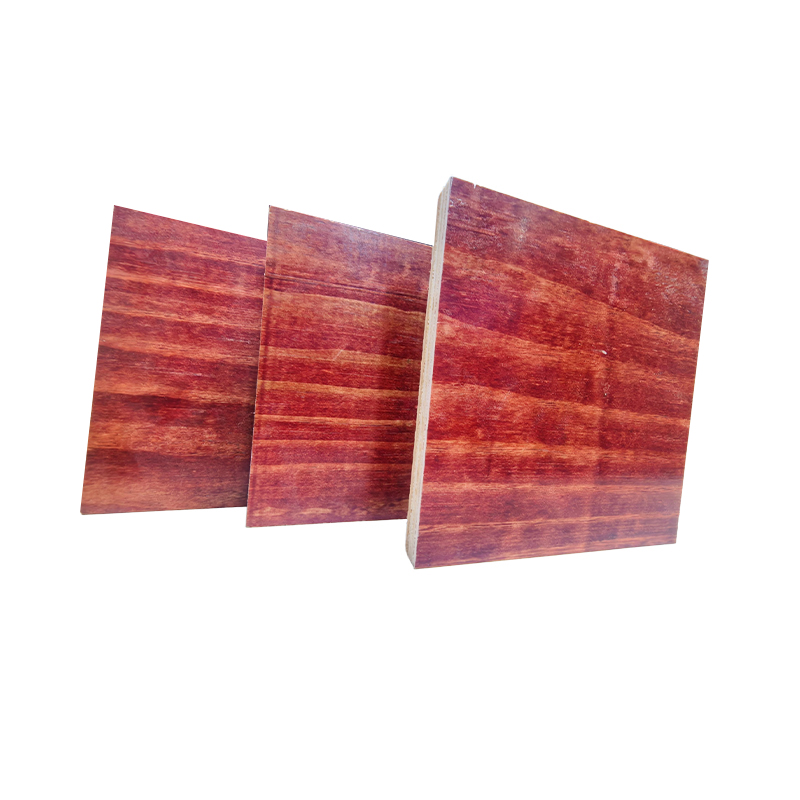

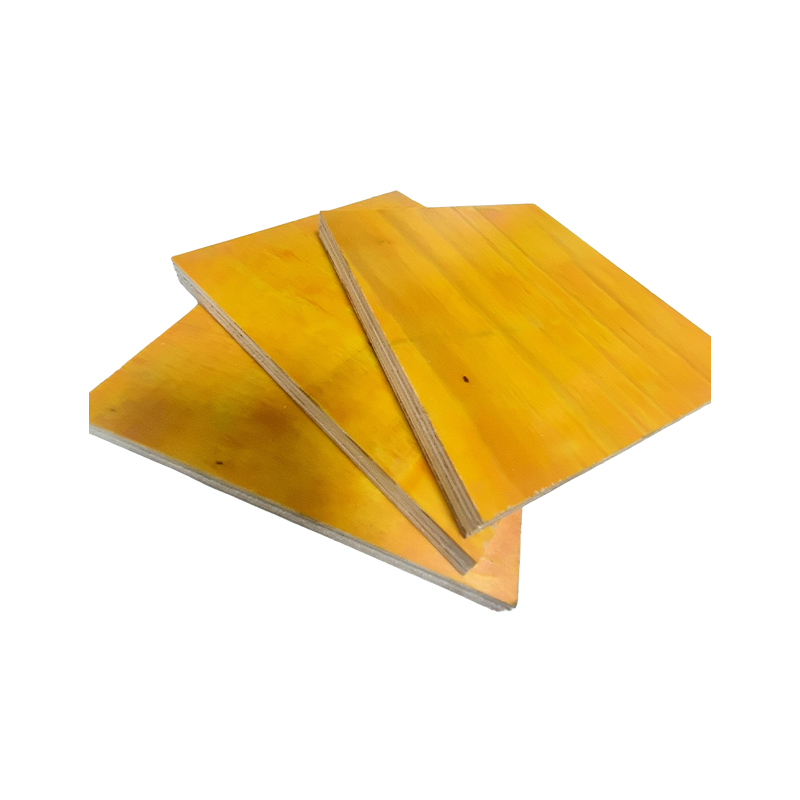

In modern construction engineering, formwork systems are the "molds" for shaping concrete structures, and their performance directly affects the geometric accuracy, surface quality, and construction efficiency of components. Building red board—a type of plywood formwork with eucalyptus or pine core material and a red phenolic resin film coating—has become one of the most widely used wooden formworks in domestic housing construction, bridges, and municipal engineering projects due to its excellent comprehensive performance. Particularly noteworthy is that even after 5, 10, or even more cycles of disassembly, handling, and pouring, high-quality red board can still maintain good flatness and structural strength. This durability is not accidental, but stems from its scientific material selection, precise lamination process, and functional surface treatment—a triple guarantee.

1. High-Quality Core Material: Synergistic Advantages of Eucalyptus and Pine

The core layer of building red board often uses fast-growing eucalyptus veneer, known for its dense wood, straight grain, and long fibers, resulting in excellent bending strength and modulus of elasticity. The surface layer typically uses pine veneer, due to its high resin content and strong corrosion resistance, effectively resisting the erosion of the alkaline environment of concrete. Some high-end products employ a "pine-eucalyptus-pine" or "eucalyptus-pine composite" structure, allowing the surface layer to resist alkali while the core layer bears the load under the lateral pressure of concrete, creating complementary mechanical properties. More importantly, all veneers undergo rigorous drying before hot pressing, significantly reducing the risk of warping and deformation caused by moisture absorption and expansion or drying shrinkage during use, laying the foundation for dimensional stability for multiple reuses.

2. High-Strength Adhesive System: Key to Resisting Hydrothermal Aging

The core reason why red board can be repeatedly used in humid and alkaline concrete environments lies in its use of water-resistant and alkali-resistant phenolic resin adhesive as the interlayer bonding agent. Compared to ordinary urea-formaldehyde resin, phenolic resin has a three-dimensional network cross-linked structure, exhibiting excellent resistance to boiling water and aging. Even under high-temperature and high-humidity summer construction conditions or winter steam curing conditions, the adhesive layer maintains a strong bond, preventing veneer delamination (detachment)—a major cause of early failure in ordinary wooden formwork.

3. Red Coating: Functional Protective Layer

The distinctive red color of the building red board is actually a kraft paper coating impregnated with phenolic resin. This coating not only provides the board with a smooth and dense release surface but also offers multiple functions:

Waterproof and Alkali-proof: Prevents moisture and cement slurry from penetrating the board, preventing the core material from absorbing water and swelling;

Abrasion-resistant and Scratch-resistant: Protects the board surface from scratches by reinforcing bars or tools during demolding and hoisting;

Easy Demolding: The smooth surface reduces concrete adhesion, simplifies cleaning, and extends service life.

High-quality coatings show no bubbling or peeling after 24 hours of boiling water, ensuring integrity even after multiple uses and continued protective function.

4. Structural Design and Edge Treatment: Details Determine Lifespan

To enhance turnover performance, high-end red board also emphasizes detail optimization: the edges are sealed with edge-sealing paint or special adhesive strips to prevent moisture intrusion from the end faces; thickness tolerance is controlled within ±0.3mm to ensure tight joints and no grout leakage; chamfering at the four corners reduces stress concentration and prevents cracking. These small design features significantly delay common failure modes such as edge delamination and corner damage.

Building red board maintains good flatness and strength even after multiple turnovers, a result of the deep integration of materials science and engineering practice. With the toughness of eucalyptus and the stability of pine as its framework, and the strength of phenolic adhesive and the protection of the coating as its outer layer, it withstands the harsh test of concrete. Therefore, it is not only an economical and efficient construction choice but also a reliable partner in ensuring project quality and progress. In today's increasingly important era of green building and resource conservation, the high turnover rate of red board aligns with the industry's sustainable development direction, continuing to write "excellence in the ordinary" on the vast construction sites.

1. High-Quality Core Material: Synergistic Advantages of Eucalyptus and Pine

The core layer of building red board often uses fast-growing eucalyptus veneer, known for its dense wood, straight grain, and long fibers, resulting in excellent bending strength and modulus of elasticity. The surface layer typically uses pine veneer, due to its high resin content and strong corrosion resistance, effectively resisting the erosion of the alkaline environment of concrete. Some high-end products employ a "pine-eucalyptus-pine" or "eucalyptus-pine composite" structure, allowing the surface layer to resist alkali while the core layer bears the load under the lateral pressure of concrete, creating complementary mechanical properties. More importantly, all veneers undergo rigorous drying before hot pressing, significantly reducing the risk of warping and deformation caused by moisture absorption and expansion or drying shrinkage during use, laying the foundation for dimensional stability for multiple reuses.

2. High-Strength Adhesive System: Key to Resisting Hydrothermal Aging

The core reason why red board can be repeatedly used in humid and alkaline concrete environments lies in its use of water-resistant and alkali-resistant phenolic resin adhesive as the interlayer bonding agent. Compared to ordinary urea-formaldehyde resin, phenolic resin has a three-dimensional network cross-linked structure, exhibiting excellent resistance to boiling water and aging. Even under high-temperature and high-humidity summer construction conditions or winter steam curing conditions, the adhesive layer maintains a strong bond, preventing veneer delamination (detachment)—a major cause of early failure in ordinary wooden formwork.

3. Red Coating: Functional Protective Layer

The distinctive red color of the building red board is actually a kraft paper coating impregnated with phenolic resin. This coating not only provides the board with a smooth and dense release surface but also offers multiple functions:

Waterproof and Alkali-proof: Prevents moisture and cement slurry from penetrating the board, preventing the core material from absorbing water and swelling;

Abrasion-resistant and Scratch-resistant: Protects the board surface from scratches by reinforcing bars or tools during demolding and hoisting;

Easy Demolding: The smooth surface reduces concrete adhesion, simplifies cleaning, and extends service life.

High-quality coatings show no bubbling or peeling after 24 hours of boiling water, ensuring integrity even after multiple uses and continued protective function.

4. Structural Design and Edge Treatment: Details Determine Lifespan

To enhance turnover performance, high-end red board also emphasizes detail optimization: the edges are sealed with edge-sealing paint or special adhesive strips to prevent moisture intrusion from the end faces; thickness tolerance is controlled within ±0.3mm to ensure tight joints and no grout leakage; chamfering at the four corners reduces stress concentration and prevents cracking. These small design features significantly delay common failure modes such as edge delamination and corner damage.

Building red board maintains good flatness and strength even after multiple turnovers, a result of the deep integration of materials science and engineering practice. With the toughness of eucalyptus and the stability of pine as its framework, and the strength of phenolic adhesive and the protection of the coating as its outer layer, it withstands the harsh test of concrete. Therefore, it is not only an economical and efficient construction choice but also a reliable partner in ensuring project quality and progress. In today's increasingly important era of green building and resource conservation, the high turnover rate of red board aligns with the industry's sustainable development direction, continuing to write "excellence in the ordinary" on the vast construction sites.