How can building formwork gold board eliminate common quality defects such as honeycomb and pitting in concrete?

Release Time : 2025-12-31

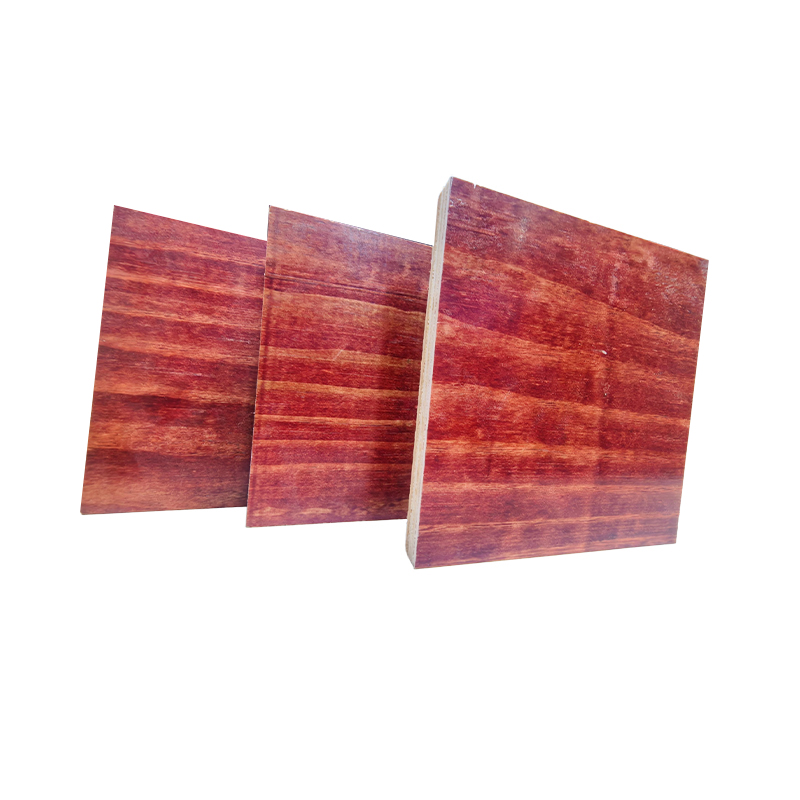

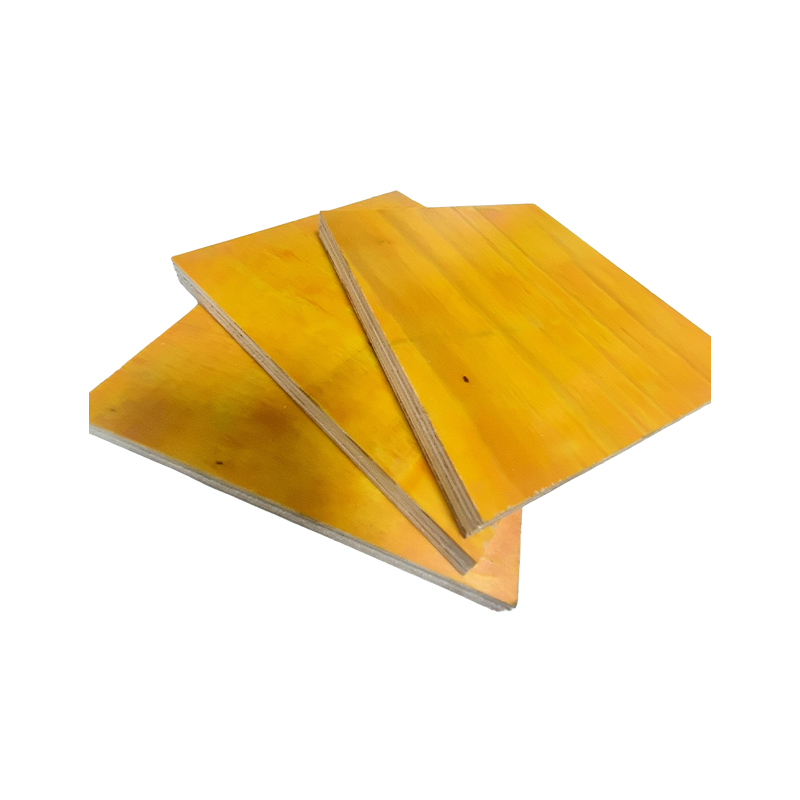

In concrete structure construction, surface defects such as honeycomb, pitting, air holes, and sand streaks are not only aesthetic issues, but may also indicate insufficient internal density, affecting structural durability and waterproofing performance. Traditional wooden formwork, due to its loose material, high water absorption, and rough surface, is prone to uneven moisture loss, air bubble retention, or grout loss during pouring, leading to various surface quality problems. High-performance building formwork, known as "gold board"—whether film-coated wood formwork, aluminum alloy formwork, or special engineering wood formwork—fundamentally changes the interface between concrete and formwork with its highly smooth and dense surface, becoming a key guarantee for achieving fair-faced concrete and eliminating common quality defects.

The name "gold board" comes not only from its bright, metallic appearance, but also from its superior surface treatment process. Taking film-coated wooden formwork as an example, although the base material is wood, its surface is covered with a high-strength phenolic resin film or melamine film, forming a continuous, closed, and non-absorbent barrier. Aluminum alloy formwork, on the other hand, undergoes precision rolling and anodizing to achieve mirror-like flatness and a chemically inert surface. These treatments ensure that when the formwork comes into contact with fresh concrete, it neither absorbs moisture nor reacts adversely with the cement paste, ensuring that the concrete maintains a uniform water-cement ratio and fluidity during the initial setting stage, creating ideal conditions for thorough compaction.

During the pouring process, air inevitably gets trapped inside the concrete. If the formwork surface is rough or porous, air bubbles are easily trapped at the interface and difficult to escape, eventually forming pits or small holes. The smooth surface of the aluminum alloy formwork greatly reduces the possibility of air bubble adhesion, allowing it to float and escape more easily under vibration. At the same time, the dense formwork will not deform due to water absorption, expansion, or local softening, avoiding uneven concrete surfaces caused by micro-unevenness in the formwork surface. This stable physical interface allows concrete to faithfully replicate the flatness of the formwork, achieving a "what you see is what you get" molding effect.

Furthermore, building formwork gold board typically eliminates the need for traditional oil-based release agents. Ordinary wooden formwork often requires large amounts of release agent for easy demolding; uneven application can leave oil stains, color differences, or hinder cement hydration, causing localized powdering or sticking. Gold board, with its low surface energy and non-adhesive properties, requires only a small amount of environmentally friendly release agent or even no agent at all, achieving clean and efficient demolding. This protects the integrity of the concrete surface structure and avoids secondary pollution.

From a construction system perspective, gold board employs standardized, modular designs with tight joints and smooth surfaces. Combined with a precise support system, it effectively prevents grout leakage—a major cause of sand lines and honeycombing. When the formwork has high overall rigidity and does not deform, the concrete will not bulge or shift under lateral pressure, further ensuring structural geometric accuracy and surface consistency.

More importantly, this high-quality finish directly reduces the need for later repairs, sanding, and plastering. In the trend of advocating "lean construction" and "plaster-free delivery," building formwork gold board not only improves building quality but also reduces labor costs and material waste, driving the transformation of construction towards green and efficient practices.

In summary, building formwork gold board, through its smooth and dense surface characteristics, optimizes the concrete forming environment from the source, effectively inhibiting core factors leading to honeycomb and pitted surfaces, such as moisture migration, air bubble retention, and grout loss. It is not just a formwork, but a "sculptor's knife" for concrete aesthetics and structural quality. In today's pursuit of high-quality construction, a high-quality gold board silently supports mirror-like concrete walls, allowing architectural beauty to begin with precision and cleanliness down to the millimeter.

The name "gold board" comes not only from its bright, metallic appearance, but also from its superior surface treatment process. Taking film-coated wooden formwork as an example, although the base material is wood, its surface is covered with a high-strength phenolic resin film or melamine film, forming a continuous, closed, and non-absorbent barrier. Aluminum alloy formwork, on the other hand, undergoes precision rolling and anodizing to achieve mirror-like flatness and a chemically inert surface. These treatments ensure that when the formwork comes into contact with fresh concrete, it neither absorbs moisture nor reacts adversely with the cement paste, ensuring that the concrete maintains a uniform water-cement ratio and fluidity during the initial setting stage, creating ideal conditions for thorough compaction.

During the pouring process, air inevitably gets trapped inside the concrete. If the formwork surface is rough or porous, air bubbles are easily trapped at the interface and difficult to escape, eventually forming pits or small holes. The smooth surface of the aluminum alloy formwork greatly reduces the possibility of air bubble adhesion, allowing it to float and escape more easily under vibration. At the same time, the dense formwork will not deform due to water absorption, expansion, or local softening, avoiding uneven concrete surfaces caused by micro-unevenness in the formwork surface. This stable physical interface allows concrete to faithfully replicate the flatness of the formwork, achieving a "what you see is what you get" molding effect.

Furthermore, building formwork gold board typically eliminates the need for traditional oil-based release agents. Ordinary wooden formwork often requires large amounts of release agent for easy demolding; uneven application can leave oil stains, color differences, or hinder cement hydration, causing localized powdering or sticking. Gold board, with its low surface energy and non-adhesive properties, requires only a small amount of environmentally friendly release agent or even no agent at all, achieving clean and efficient demolding. This protects the integrity of the concrete surface structure and avoids secondary pollution.

From a construction system perspective, gold board employs standardized, modular designs with tight joints and smooth surfaces. Combined with a precise support system, it effectively prevents grout leakage—a major cause of sand lines and honeycombing. When the formwork has high overall rigidity and does not deform, the concrete will not bulge or shift under lateral pressure, further ensuring structural geometric accuracy and surface consistency.

More importantly, this high-quality finish directly reduces the need for later repairs, sanding, and plastering. In the trend of advocating "lean construction" and "plaster-free delivery," building formwork gold board not only improves building quality but also reduces labor costs and material waste, driving the transformation of construction towards green and efficient practices.

In summary, building formwork gold board, through its smooth and dense surface characteristics, optimizes the concrete forming environment from the source, effectively inhibiting core factors leading to honeycomb and pitted surfaces, such as moisture migration, air bubble retention, and grout loss. It is not just a formwork, but a "sculptor's knife" for concrete aesthetics and structural quality. In today's pursuit of high-quality construction, a high-quality gold board silently supports mirror-like concrete walls, allowing architectural beauty to begin with precision and cleanliness down to the millimeter.