How does building red board resist moisture erosion during concrete pouring?

Release Time : 2026-01-14

In construction engineering, although formwork is a temporary structure, it directly determines the final geometric accuracy and surface quality of the concrete. Concrete itself is a high-moisture, fluid material that continuously releases large amounts of moisture and alkaline substances during pouring, vibration, and initial setting. If the formwork cannot effectively resist this moisture erosion, it is prone to water absorption and expansion, interlayer delamination, bulging, and even structural failure, affecting not only the molding effect but also potentially causing safety hazards such as support instability. The reason building red board (commonly known as "small red board" or "large red board") can reliably serve in harsh wet working environments for a long time lies in its high-density wood core layer and the synergistic protective system of a special waterproof adhesive, which together construct a solid barrier against moisture erosion.

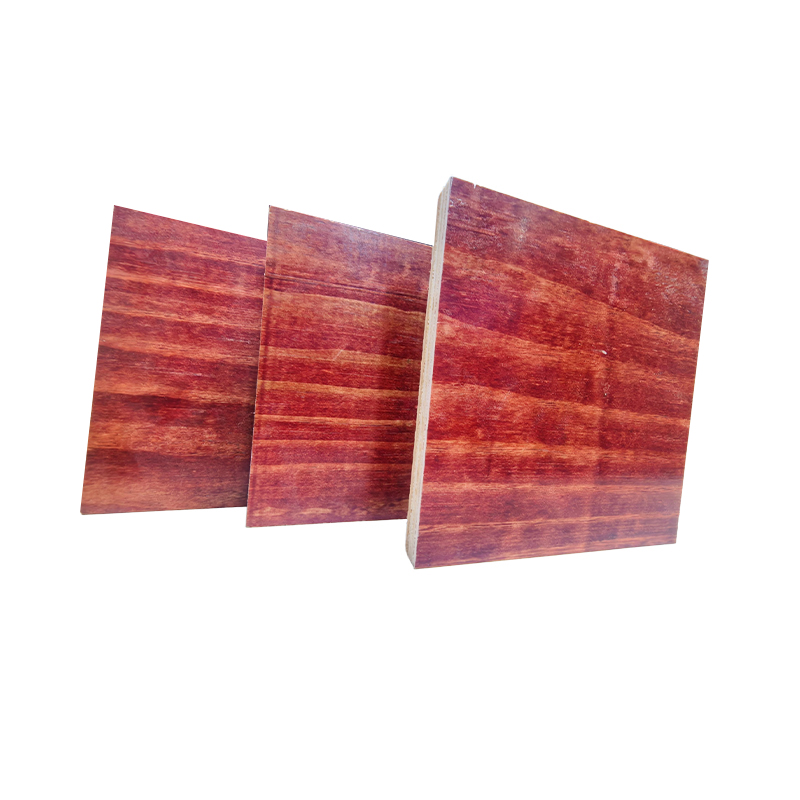

Its moisture resistance primarily stems from the dense structure of the core wood layer. High-quality building red board is made from multiple layers of rotary-cut veneer, interlocked and pressed under high temperature and pressure. The core wood undergoes strict selection and drying treatment, with precise moisture content control, tightly packed fibers, and low porosity. This high-density structure significantly reduces the channels for moisture penetration, making the boards less prone to rapid water absorption and expansion when in contact with wet concrete. Even if the surface is briefly damp, the interior remains dimensionally stable, preventing formwork joints from opening or supports from loosening due to localized deformation, thus ensuring clear outlines and sharp edges of concrete components.

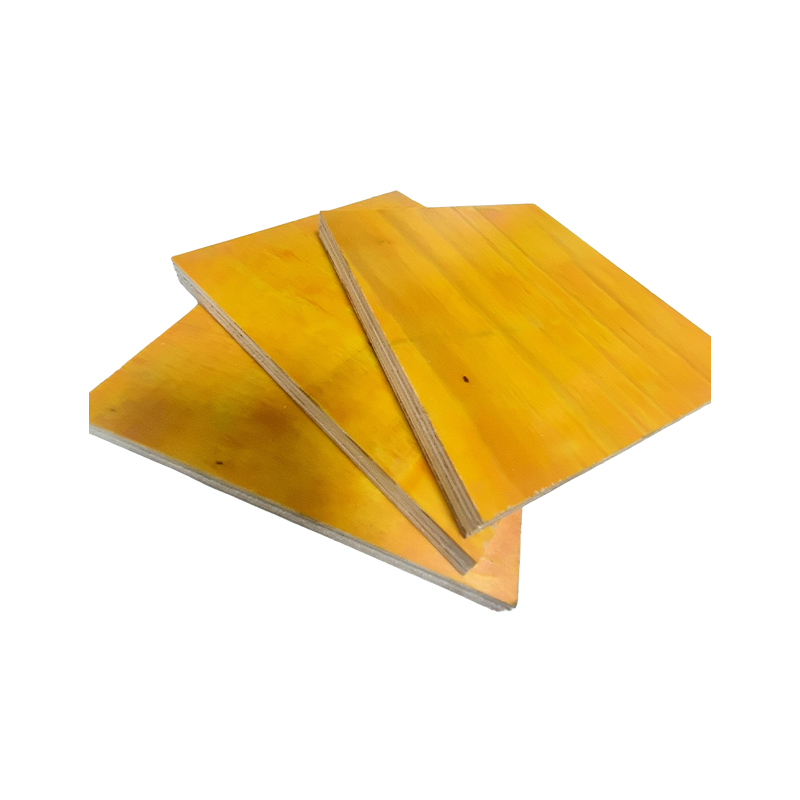

More importantly, the chemical protection provided by the waterproof adhesive is crucial. Ordinary plywood often uses conventional adhesives such as urea-formaldehyde resin, which are easily hydrolyzed when exposed to water, leading to decreased interlayer adhesion and delamination. Building red board, on the other hand, uses phenolic resin or modified melamine-based waterproof adhesives, which possess excellent water resistance, alkali resistance, and thermal stability. During high-temperature hot pressing, the adhesive fully impregnates the wood fibers and forms a three-dimensional cross-linked network. After curing, it is almost insoluble in water and resists the erosion of alkaline liquids released from concrete. Even in prolonged humid environments, the adhesive layer remains strong, ensuring a tight bond between each veneer layer and maintaining overall mechanical properties.

Furthermore, the surface coating further strengthens the moisture barrier. The iconic red surface of building red board is typically made of resin-impregnated abrasion-resistant paper or phenolic film, giving it a striking appearance and forming a dense, smooth physical barrier. This coating effectively prevents concrete slurry from directly contacting the wood substrate, reducing the penetration of moisture and cement slurry, while facilitating demolding and preventing the board surface from being corroded or roughened by cement residue. Even after multiple uses, damaged areas of the coating do not deteriorate rapidly due to the dual protection of the core layer and adhesive.

It is worth mentioning that edge sealing is often overlooked but crucial. High-quality red boards undergo edge sealing or gluing before leaving the factory to prevent moisture from penetrating through the capillary pores on the end face. This detail significantly slows down the rate of moisture diffusion between layers, avoiding gradual damage "from the edge to the core" and extending the reusability of the formwork.

Ultimately, the ability of building red board to resist moisture erosion does not rely on the advantages of a single material, but rather on the systematic integration of a high-density core layer, waterproof adhesive, and surface coating to achieve comprehensive protection that is both strong inside and strong outside. It allows a seemingly ordinary wooden plank to remain sturdy and stable amidst the mud and water of a construction site; silently guarding the form and texture of the building through repeated concrete pours. When the formwork is removed, revealing a smooth, mirror-like concrete wall, it is this red plank that, with its silent resilience, fulfills its promise of project quality—power lies within the ordinary.

Its moisture resistance primarily stems from the dense structure of the core wood layer. High-quality building red board is made from multiple layers of rotary-cut veneer, interlocked and pressed under high temperature and pressure. The core wood undergoes strict selection and drying treatment, with precise moisture content control, tightly packed fibers, and low porosity. This high-density structure significantly reduces the channels for moisture penetration, making the boards less prone to rapid water absorption and expansion when in contact with wet concrete. Even if the surface is briefly damp, the interior remains dimensionally stable, preventing formwork joints from opening or supports from loosening due to localized deformation, thus ensuring clear outlines and sharp edges of concrete components.

More importantly, the chemical protection provided by the waterproof adhesive is crucial. Ordinary plywood often uses conventional adhesives such as urea-formaldehyde resin, which are easily hydrolyzed when exposed to water, leading to decreased interlayer adhesion and delamination. Building red board, on the other hand, uses phenolic resin or modified melamine-based waterproof adhesives, which possess excellent water resistance, alkali resistance, and thermal stability. During high-temperature hot pressing, the adhesive fully impregnates the wood fibers and forms a three-dimensional cross-linked network. After curing, it is almost insoluble in water and resists the erosion of alkaline liquids released from concrete. Even in prolonged humid environments, the adhesive layer remains strong, ensuring a tight bond between each veneer layer and maintaining overall mechanical properties.

Furthermore, the surface coating further strengthens the moisture barrier. The iconic red surface of building red board is typically made of resin-impregnated abrasion-resistant paper or phenolic film, giving it a striking appearance and forming a dense, smooth physical barrier. This coating effectively prevents concrete slurry from directly contacting the wood substrate, reducing the penetration of moisture and cement slurry, while facilitating demolding and preventing the board surface from being corroded or roughened by cement residue. Even after multiple uses, damaged areas of the coating do not deteriorate rapidly due to the dual protection of the core layer and adhesive.

It is worth mentioning that edge sealing is often overlooked but crucial. High-quality red boards undergo edge sealing or gluing before leaving the factory to prevent moisture from penetrating through the capillary pores on the end face. This detail significantly slows down the rate of moisture diffusion between layers, avoiding gradual damage "from the edge to the core" and extending the reusability of the formwork.

Ultimately, the ability of building red board to resist moisture erosion does not rely on the advantages of a single material, but rather on the systematic integration of a high-density core layer, waterproof adhesive, and surface coating to achieve comprehensive protection that is both strong inside and strong outside. It allows a seemingly ordinary wooden plank to remain sturdy and stable amidst the mud and water of a construction site; silently guarding the form and texture of the building through repeated concrete pours. When the formwork is removed, revealing a smooth, mirror-like concrete wall, it is this red plank that, with its silent resilience, fulfills its promise of project quality—power lies within the ordinary.